In the complex world of metal fabrication, where precision, structural integrity, and safety are paramount, clear communication is not merely a courtesy—it’s an absolute necessity. At the heart of this communication lies the sophisticated language of welding symbols. These standardized graphical representations convey a vast amount of information about a weld joint, ensuring that the design intent of an engineer is accurately translated into a physical weld by a skilled welder, and ultimately inspected by a qualified professional.

For anyone involved in design, manufacturing, or quality assurance, mastering the interpretation of welding symbols is non-negotiable. Misunderstandings can lead to costly rework, structural failures, or even catastrophic safety incidents. This comprehensive guide will demystify the intricacies of welding symbols, breaking down each component according to the widely accepted American Welding Society (AWS) standards. By the end, you’ll gain a profound understanding of how these symbols serve as the backbone of efficient, error-free fabrication.

The Anatomy of a Welding Symbol: Building Blocks of Precision

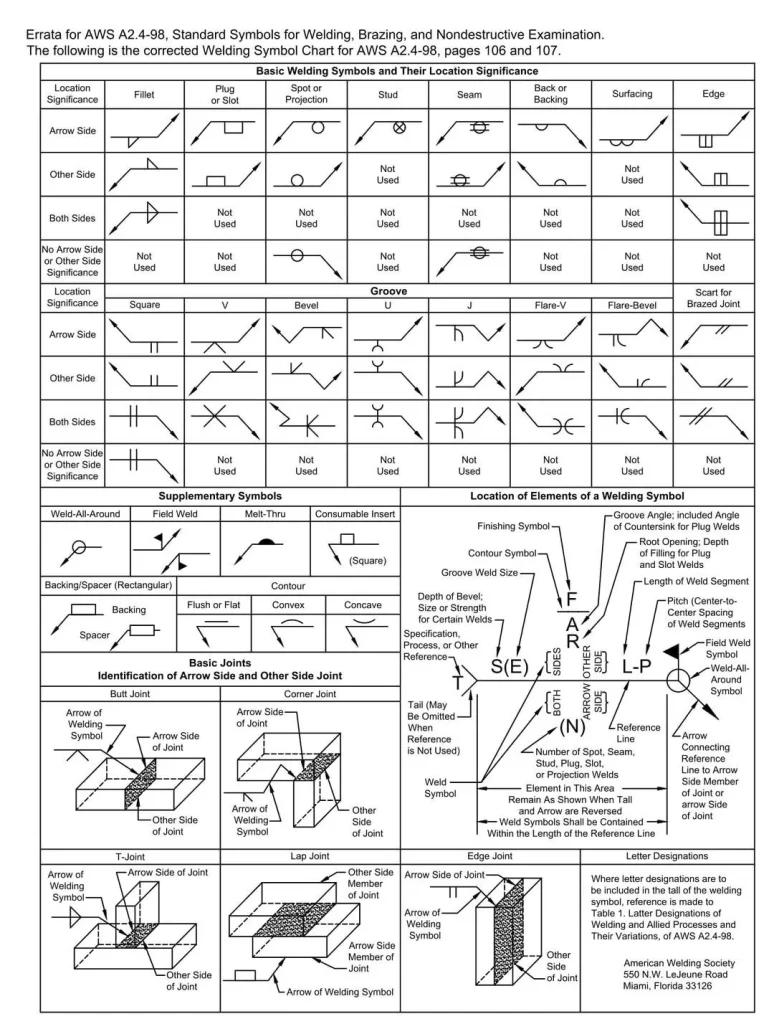

A standard welding symbol is more than just a single mark; it’s a meticulously designed collection of elements, each providing specific instructions about the desired weld. Think of it as a condensed instruction manual for every joint. The primary components include:

- Reference Line: The horizontal line forming the base of the welding symbol. All other information, except for the arrow and the tail, branches from this line.

- Arrow: Originating from one end of the reference line, the arrow points directly to the joint where the weld is to be applied. Its direction is crucial, as it defines the “arrow side” and “other side” of the weld.

- Basic Weld Symbols: Placed directly on the reference line, these symbols denote the type of weld required (e.g., fillet, groove, spot).

- Supplementary Symbols: These symbols provide additional instructions about the weld, such as its contour, finish, or whether it’s a “weld all around.”

- Dimensions and Other Data: Numbers indicating the size, length, pitch, groove angle, or other specific measurements associated with the weld.

- Tail: An open “V” shape at the end of the reference line (opposite the arrow), often used for specifying the welding process, filler material, or other specific notes not covered by standard symbols.

Understanding how these components interrelate is the key to accurate interpretation. Let’s delve into each part with greater detail.

I. The Foundational Elements: Reference Line and Arrow

These two components establish the context for every other piece of information within the symbol.

1. The Reference Line

The reference line is the bedrock of the entire welding symbol. It is typically drawn horizontally, and almost all welding symbol information is placed either above or below this line. The precise location of weld symbols on the reference line—specifically, whether they are on the “arrow side” or “other side”—is fundamental to correct interpretation.

- Location of Symbols:

- Arrow Side: If the basic weld symbol is placed below the reference line, it indicates a weld on the side of the joint to which the arrow points.

- Other Side: If the basic weld symbol is placed above the reference line, it indicates a weld on the opposite side of the joint from where the arrow points.

- Both Sides: If identical weld symbols appear on both sides (above and below) the reference line, it means the specified weld should be applied to both sides of the joint.

This arrow side/other side convention is one of the most critical aspects to master. Misinterpreting this can lead to a weld being placed on the wrong side of the joint, potentially compromising structural integrity.

2. The Arrow

The arrow is the pointing mechanism of the welding symbol. It connects the reference line to the specific joint location or a member of a joint that needs welding.

- Directionality: The arrow always points directly at the weld location. For single welds, this is straightforward. For multiple joints or complex assemblies, the arrow clearly designates which specific joint the symbol refers to.

- Significance: Beyond just pointing, the arrow’s interaction with the reference line (and where the weld symbol is placed) dictates the arrow-side/other-side rule described above.

- Compound Arrows: Sometimes, the arrow might branch to point to multiple joints that require the same welding specification. This simplifies complex drawings by reducing the number of individual welding symbols needed.

II. Basic Weld Symbols: Defining the Joint Configuration

Basic weld symbols are the graphical shorthand for different types of welds, communicating the shape and form of the fused material. These are always placed on the reference line, directly corresponding to either the arrow side or other side.

1. Fillet Weld (∇)

- Description: The most common weld type, used primarily on tee, lap, and corner joints. It has a triangular cross-section. The symbol resembles a right triangle.

- Placement: The upright leg of the triangle is always oriented to the left, regardless of whether it’s an arrow-side or other-side weld.

- Dimensions: The size (leg length) of the fillet weld is written to the left of the fillet symbol. If the leg lengths are unequal, both dimensions are specified.

- Example Use: Attaching a support bracket to a main beam, lap joints in sheet metal.

2. Groove Welds (Various Types)

Groove welds involve preparing the edges of the base metal to create a “groove” that is then filled with weld metal. There are several variations:

- Square Groove (I):

- Description: No edge preparation needed, typically for thinner materials where complete penetration can be achieved.

- Symbol: A simple “I” shape.

- Use: Sheet metal, thin plates, where full penetration without beveling is feasible.

- Bevel Groove (V with one side straight):

- Description: One joint member is beveled, the other remains square.

- Symbol: A “V” shape, with one side straight.

- Important: The straight side of the “V” always goes toward the joint member to which the arrow points. This is crucial for proper joint preparation.

- Dimensions: Root opening, groove angle, and depth of preparation (if applicable) are specified.

- Use: Creating a V-groove in one plate edge when joining to another flat plate.

- V-Groove (V):

- Description: Both joint members are beveled to form a “V” shape when brought together.

- Symbol: A simple “V” shape.

- Use: Common for butt joints in thicker materials, ensuring full penetration.

- U-Groove (U):

- Description: Offers a smoother, wider groove than a V-groove, requiring more machining but potentially less filler metal for the same strength due to reduced angle.

- Symbol: A “U” shape.

- Use: Heavy plates and critical applications where material efficiency and improved penetration are desired.

- J-Groove (J):

- Description: Similar to a U-groove but with one curved side and one straight side. Often used for T-joints where one member is prepared with a J-bevel.

- Symbol: A “J” shape.

- Important: Similar to bevel grooves, the straight side always faces the arrow-side member.

- Use: Often in thick sections to minimize weld volume and distortion, especially in pipe-to-plate joints.

- Flare-V Groove & Flare-Bevel Groove:

- Description: Used when welding together rounded or flanged edges, where the natural curvature forms a groove. No machining of a bevel is typically needed.

- Symbol: Resemble curved lines with an indication of the weld on the convex side.

- Use: Often for pipe sections or curved parts that are fit together.

- Other Groove Symbols: Less common, but other specific preparations exist and would have their own designated symbols or be described in the tail.

3. Plug and Slot Welds (◯ / ☐ with internal dots/lines)

- Description: Used for attaching one plate on top of another using holes or slots cut into the top plate, then filling these with weld metal. Offers good strength and often a flush surface.

- Symbol: A circle for plug welds (referencing a round hole) or a rectangle for slot welds.

- Dimensions: Diameter/width, depth of filling, length of slot, and pitch (center-to-center spacing) are specified.

- Use: Securing plates, shear connections, replacing rivets in some applications.

4. Spot Welds (•)

- Description: Resistance welding method used to join two or more metal sheets by creating small, localized melts. Often used in automotive body construction.

- Symbol: A single circle, placed on the reference line (usually for arrow or other side) or above the reference line (for a projection weld).

- Dimensions: Diameter of the spot, strength in pounds, and pitch (center-to-center spacing) are given.

- Use: Lap joints of sheet metal, especially in high-volume production.

5. Seam Welds (X with circle through it / Line with ends)

- Description: A continuous weld along a joint, often achieved by resistance welding using rotating electrodes (resistance seam welding) or by continuous arc welding (arc seam welding).

- Symbol: For resistance seam, an “X” with a circle cutting through its middle. For arc seam, two parallel lines connected at the ends forming a long rectangle with rounded ends.

- Dimensions: Width, length, or total length of weld; strength, and pitch (if intermittent).

- Use: Making liquid or gas-tight joints in sheet metal, such as fuel tanks or drums.

6. Surfacing Weld (∩ – concave upward arc)

- Description: Used to build up the surface of a metal component, often for repair, to restore original dimensions, or to deposit wear-resistant material.

- Symbol: An upward-curved arc, resembling a rainbow.

- Dimensions: Height of the deposited weld metal, often accompanied by length or area specifications in the tail.

- Use: Hardfacing components, restoring worn machine parts, building up sections for later machining.

7. Edge Weld (Edge line)

- Description: Used on flanged edges or members that are approximately parallel. The weld fuses the edges of the components.

- Symbol: Resembles an elongated “L” or an upright box missing its top, representing the fused edges.

- Use: Joining edges of sheet metal in lap or corner joints.

8. Back or Backing Weld

- Description: A weld placed on the root side of a groove weld, or on the opposite side of a single-sided groove weld, to ensure full penetration and reinforce the joint.

- Symbol: A curved line.

- Note: If the purpose is specifically for a backing bar (temporary or permanent), a backing symbol (a rectangle) would be used, with additional notes in the tail. The backing weld symbol typically refers to a small fusion pass.

- Use: Achieving full penetration on critical butt joints.

III. Supplementary Symbols: Adding Detail and Context

Supplementary symbols refine the instructions provided by the basic weld symbols, covering aspects like aesthetics, finish, and the physical location of welding.

1. Weld-All-Around (◯ at junction of arrow and reference line)

- Description: This circle at the intersection of the arrow and reference line indicates that the weld specified on the symbol should extend continuously around the entire perimeter of the joint.

- Use: Any joint that forms a closed loop, like a pipe-to-flange connection, or a gusset plate attached to all its contact edges. Saves needing to draw a detailed isometric view for the weld.

2. Field Weld (∆ at junction of arrow and reference line)

- Description: A flag symbol placed at the intersection signifies that the weld is to be performed “in the field,” meaning at the erection site rather than in the fabrication shop.

- Significance: Field welds often require different planning regarding equipment, environmental controls, and skilled labor. It signals unique challenges compared to shop welding.

3. Contour Symbols (Straight Line / Concave Curve / Convex Curve)

These symbols specify the desired profile of the weld bead surface.

- Flush or Flat Contour (─): A straight line drawn above or below the basic weld symbol, indicating that the weld face should be approximately flat, even with the surface of the base metal.

- Concave Contour (‿): A downward-curved line, indicating that the weld face should be dished inward.

- Convex Contour (∩): An upward-curved line, indicating that the weld face should be crowned or bulged outward.

- Use: Critical for fluid flow, appearance, fatigue resistance, or to meet specific fit-up requirements for subsequent components.

4. Finish Symbols (G, M, C, R, H, U, P)

These letters indicate the method used to achieve the desired contour, often placed near the contour symbol.

- G (Grinding): The weld is to be ground to achieve the contour.

- M (Machining): The weld is to be machined.

- C (Chipping): The weld is to be chipped.

- R (Rolling): The weld is to be rolled.

- H (Hammering): The weld is to be hammered.

- U (Unspecified): The method of finish is left to the contractor’s discretion.

- P (Planing): The weld is to be planed.

- Significance: Specifying the finish method affects production time, cost, and final appearance/performance.

5. Melt-Through (Rectangle filled with semi-circle or triangle, below reference line)

- Description: This symbol indicates that complete joint penetration with visible reinforcement on the root side is required. It ensures full fusion through the thickness of the material.

- Use: Critical for strength, especially in thin sections or when specific code requirements dictate full root penetration.

6. Backing/Spacer (Rectangle or Dash for backing bar)

- Description: Indicates that a backing material (often a metal strip, ceramic, or gas) is used during welding. The backing itself could be consumable or non-consumable. If a permanent backing bar is to be used and fused into the joint, this symbol often applies.

- Use: Helps control root penetration, prevents burn-through, and simplifies welding setup.

7. Consumable Insert (Square within a square / letter “CI” in tail)

- Description: Indicates that a pre-placed, specially shaped consumable material is inserted into the root of the joint prior to welding. It ensures a clean, controlled root pass.

- Use: High-integrity pipe welding, nuclear components, aerospace where root quality is paramount.

IV. Dimensions, Notations, and the Tail

Beyond the basic visual symbols, numbers and specific notations provide critical quantifiable details.

1. Weld Size

- Fillet Welds: Leg size (or throat for specific cases) is typically written to the left of the fillet symbol.

- Groove Welds: Depth of preparation, groove angle, and root opening are crucial.

- Depth of preparation: Height of the prepared groove.

- Groove angle: The total angle included in the groove (e.g., for a V-groove).

- Root Opening (or Root Gap): The separation distance between the joint members at the root of the groove, specified inside the weld symbol.

2. Weld Length and Pitch (Intermittent Welds)

For intermittent (non-continuous) welds:

- Length: The actual length of each weld segment is written to the right of the weld symbol.

- Pitch: The center-to-center distance between weld segments is placed to the right of the length, separated by a dash (e.g., 2-6 means 2″ long welds on 6″ centers).

- Chain Intermittent: Weld segments on both sides are aligned directly opposite each other.

- Staggered Intermittent: Weld segments on one side are offset from the segments on the other side. A staggered intermittent symbol has the staggered dimension on its opposite side compared to a chain intermittent.

3. Groove Angle (for V, Bevel, U, J-grooves)

The angle to which the joint members are prepared for a groove weld. It’s written inside the weld symbol on the reference line.

4. The Tail of the Welding Symbol

The tail is an invaluable section of the welding symbol, reserved for information that cannot be conveyed by standard symbols. This includes:

- Welding Process: Often specified here (e.g., GMAW for Gas Metal Arc Welding, GTAW for Gas Tungsten Arc Welding, SMAW for Shielded Metal Arc Welding).

- Filler Metal Specification: The specific type of electrode or filler wire to be used (e.g., E7018, ER70S-6).

- Post-weld Heat Treatment (PWHT): If required, it will be noted here (e.g., “PWHT per Spec A.3”).

- Preheat Requirements: Initial temperature required for the base metal.

- Code or Standard Reference: Any specific codes or standards that the weld must adhere to (e.g., “Per ASME Section IX”).

- Test Methods: Such as non-destructive testing (NDT) requirements.

- Other Notes: Any additional information relevant to the welding procedure that is not represented graphically.

When a symbol includes a tail, always read its contents, as it often contains critical, non-graphical instructions.

V. Common Standards and Practical Considerations

While AWS (American Welding Society) standards are predominantly used in North America, other regions adhere to ISO (International Organization for Standardization) standards.

AWS vs. ISO Standards

- AWS: Follows a convention where symbols above the reference line denote welds on the “other side,” and symbols below denote “arrow side” welds. The location relative to the reference line dictates weld placement.

- ISO: Primarily uses a single side of the reference line for basic symbols, and indicates weld side explicitly with supplementary arrow information or contextual details within the drawing. While conceptually similar in what they convey, their visual layout and some specific symbols can differ.

- Best Practice: Always confirm which standard (AWS, ISO, JIS, etc.) is being used on the blueprint or engineering drawing. Confusion between standards can lead to significant errors.

Practical Application and Importance

- Designers/Engineers: Use symbols to communicate exact joint configuration, material preparation, and quality requirements. Symbols ensure the final structure performs as intended.

- Welders/Fabricators: Interpret symbols to select the correct process, prepare materials appropriately, execute the weld with proper dimensions and penetration, and apply any necessary post-weld treatments.

- Inspectors/Quality Control: Verify that welds conform precisely to the specifications denoted by the symbols, using visual, non-destructive, and destructive testing methods.

Common Misinterpretations and Mistakes

- Arrow Side vs. Other Side: The single most common error. Always double-check where the weld symbol is relative to the reference line and the direction of the arrow.

- Missing or Misunderstood Tail Information: Neglecting the tail can mean overlooking crucial details like welding process or special instructions.

- Confusion with Intermittent Welds: Misinterpreting length vs. pitch, or chain vs. staggered intermittent.

- Incomplete Drawings: Sometimes, essential information might be missing. When in doubt, always seek clarification from the design engineer.

Conclusion: The Unspoken Language of Fabrication

Welding symbols are far more than just arbitrary marks on a blueprint; they are a sophisticated, universal language that bridges the gap between design and execution in metal fabrication. Mastering this language empowers professionals across the spectrum—from the engineer sketching the initial concept to the welder meticulously joining components and the inspector ensuring compliance.

By understanding each element of the welding symbol, its specific meaning, and how to interpret it within the broader context of an engineering drawing, you not only enhance efficiency and reduce errors but also elevate the safety and structural integrity of every project. Investing time in thoroughly learning these symbols is an investment in quality, precision, and a robust future for metal construction. Embrace the language, and unlock new levels of excellence in your welding and fabrication endeavors.

Frequently Asked Questions (FAQs) About Welding Symbols

1. Why are welding symbols important in fabrication?

Welding symbols are crucial because they provide a standardized, universal language for communicating precise welding instructions from the designer to the welder and inspector. They prevent ambiguity, reduce errors, ensure proper joint configuration, dictate specific processes, and ultimately contribute to the safety, structural integrity, and quality control of manufactured products. Without them, relying on verbal instructions or simple sketches would lead to widespread inconsistencies and potential failures.

2. What is the difference between “arrow side” and “other side” on a welding symbol?

This distinction is fundamental to correct weld placement. The “arrow side” refers to the side of the joint to which the arrow of the welding symbol directly points. The “other side” refers to the opposite side of that joint. If a basic weld symbol is placed below the reference line, the weld is to be made on the arrow side. If the symbol is placed above the reference line, the weld is on the other side. If identical symbols appear on both sides of the reference line, the weld is applied to both sides of the joint.

3. What kind of information is typically found in the “tail” of a welding symbol?

The tail of a welding symbol (the open “V” section at the end of the reference line) is reserved for supplementary information that cannot be conveyed by standard symbols. This often includes specifying the welding process (e.g., GMAW, GTAW, SMAW), the type of filler metal or electrode to be used, post-weld heat treatment requirements, preheat temperatures, references to specific codes or standards (e.g., ASME, AWS), or any other specific notes critical to the welding procedure or inspection.

4. How do intermittent welds differ from continuous welds, and how are they symbolized?

A continuous weld runs unbroken along the entire length of the joint, while an intermittent weld consists of a series of segments with un-welded spaces (gaps) between them. Intermittent welds are symbolized by adding the length of each weld segment and the “pitch” (center-to-center spacing) to the right of the basic weld symbol on the reference line (e.g., 2-6 means 2-inch long welds with a 6-inch center-to-center spacing). They can be “chain intermittent” (segments on both sides are aligned) or “staggered intermittent” (segments on opposite sides are offset).

5. What is the purpose of supplementary symbols like “Weld-All-Around” and “Field Weld”?

- Weld-All-Around (circle at the arrow/reference line junction): This symbol indicates that the specified weld should extend continuously around the entire perimeter of the joint. It saves drawing complex isometric views to convey the continuity of the weld on all sides of a closed joint (like a pipe or box section).

- Field Weld (flag at the arrow/reference line junction): This symbol signifies that the weld is to be performed at the job site or erection site, rather than in the controlled environment of a fabrication shop. It highlights the potential for different equipment, environmental factors, or labor requirements.

6. Are AWS and ISO welding symbols the same?

No, while both AWS (American Welding Society) and ISO (International Organization for Standardization) welding symbols aim to convey the same information about welds, they differ in their graphical representation and conventions. AWS is predominant in North America, while ISO standards are widely used internationally. Key differences include the arrow side/other side convention and the specific appearance of some symbols. It’s crucial to always identify which standard is being used on an engineering drawing to avoid misinterpretation.