In GTAW (Gas Tungsten Arc Welding) also known as TIG welding (Tungsten Inert Gas welding), a non consumable electrode (made up of Tungsten) is used. Tungsten is preferred due to high its high melting point (approximately 3,4100C) and high hardness.

GTAW Tungsten Electrode for orbital TIG welding

Welding Town

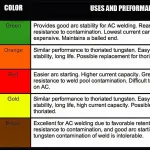

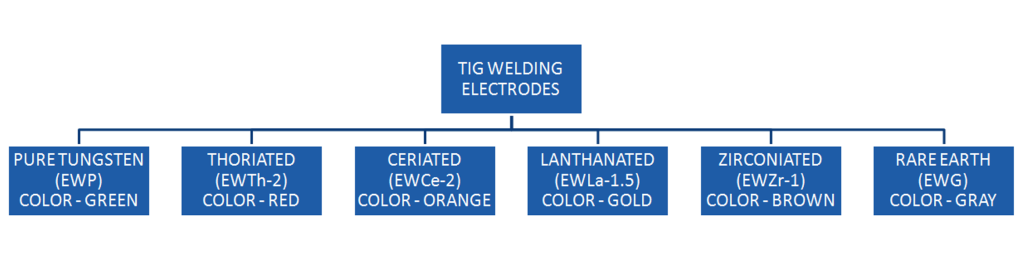

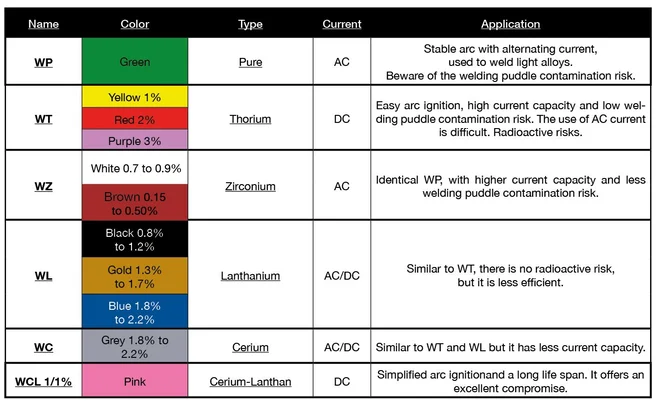

Either pure tungsten is used as electrode or it can be alloyed with other elements. These electrodes come in a variety of sizes and lengths. These electrodes are color coded to distinguish it from others. The color appears at the tip of the electrode. Different types of TIG welding electrodes are as follows;

TIG Welding (GTAW) Electrodes

- Pure Tungsten (Color Code: Green)

- Thoriated (Color Code: Red)

- Ceriated (Color Code: Orange)

- Lanthanated (Color Code: Gold)

- Zirconiated (Color Code: Brown)

- Rare Earth (Color Code: Gray)

- Pure Tungsten:

- Color Code – Green

- AWS Classification – EWP

- 99.50 % Tungsten

- Ideal for AC welding

- Excellent arc stability

- Less expensive

- Thoriated:

- Color Code: Red

- AWS Classification – EWTh-2

- Tungsten (97.30% min.) + Thorium (1.70% to 2.20%)

- Also known as 2 percent thorium

- Preferred for longevity and ease of use

- Can be used with both AC as well as DC

- Expensive and radioactive material

- Ceriated:

- Color Code: Orange

- AWS Classification – EWCe-2

- Tungsten (97.30% min.) + Cerium (1.80% to 2.20%)

- Also known as 2 percent ceriated

- Preferably used with DC welding

- Lanthanated:

- Color Code: Gold

- AWS Classification – EWLa-1.5

- Tungsten (97.80% min.) + Lanthanum (1.30% to 1.70%)

- Also known as 1.5 percent lanthanated

- Arc initiation excellent and very stable

- General purpose can be used for carbon steel and stainless steel

- Can be used with both AC and DC

- Zirconiated:

- Color Code: Brown

- AWS Classification – EWZr-1

- Tungsten (99.10% min.) + Zirconium (0.15% to 0.40%)

- Also known as 2 percent Zirconiated

- Suitable for AC welding

- Rare Earth:

- Color Code: Gray

- AWS Classification – EWG

- Contains additives of rare-earth oxides (% unspecified)

- Polarity depends upon the percentage of the rare earth oxides

- Wide range of applications

Choosing the right tungsten for aluminum TIG welding

Q: I am just getting into aluminum GTAW and I have heard many recommendations about which tungsten electrode I should use. Can you tell me how to make the right choice?

A: I will certainly try. First, let’s look at the commonly available tungsten electrodes (see Figure 1). Each type is given an AWS classification and includes a painted stripe around one end so you can easily identify the type.

The various additions to the tungsten electrode serve two purposes. First, it makes the tungsten less likely to sag or droop at high temperatures. Second, it makes it easier for the tungsten to emit electrons, which gives it a higher current-carrying capacity compared to pure tungsten.

Almost all direct current electrode negative (DCEN) welding that has been done in the past was with 2 percent thoriated electrodes, although more recently lanthanated and ceriated electrodes have become more popular for this type of welding.

However, when people started to aluminum GTAW using alternating current (AC), they found out thoriated electrodes really weren’t well-suited for that type of welding. In AC GTAW, much more energy is taken up by the tungsten than is taken up in DCEN welding. In the past the electrode choices were limited to pure tungsten or zirconiated tungsten, which could carry more current than a pure tungsten electrode of the same size. Neither of these electrodes was used with a sharpened tip. Instead, they were allowed to form a round ball on the end.

Thoriated tungsten did not form a nice round ball, but became very irregular in geometry, which produced a fluttery, irregular arc. So pure and zirconiated electrodes were preferred, and still are if your GTAW machine is an SCR/transformer type, especially an older model.

Inverter Machines and Tungsten TIG Welding

When inverter GTAW machines came on the scene, they changed everything. The balance control can be set much further toward electrode negative (EN) while still getting good arc cleaning action. Since only a little electrode positive (EP) is used, the tungsten electrode stays much cooler. In fact, the best electrodes for AC inverter GTAW machines are generally ceriated, lanthanated, and rare-earth electrodes, which are all sharpened to a point and can retain the point very well during use. Thoriated, zirconiated, and pure tungsten electrodes are not often used with AC inverter machines.