In the ever-evolving landscape of metal fabrication, where demands for precision, efficiency, and material versatility continually intensify, the advancement of welding technology remains critical. Among these innovations, Pulse MIG Welding (Pulsed Gas Metal Arc Welding – Pulsed GMAW) stands out as a transformative process. It bridges the gap between the speed and economy of traditional MIG welding and the control and aesthetic quality often associated with Gas Tungsten Arc Welding (GTAW or TIG), offering a sophisticated solution for a wide range of challenging applications.

No longer a niche technique, Pulse MIG has become an indispensable tool in modern workshops, from high-production manufacturing to intricate repair and artistic fabrication. This comprehensive guide will delve deep into the mechanics, benefits, applications, and operational considerations of Pulse MIG welding, equipping professionals and aspiring experts alike with the knowledge to harness its full potential for superior weld quality and enhanced productivity.

I. The Evolution of GMAW: Bridging the Gap

To truly appreciate Pulse MIG, it’s essential to understand its origins within the broader context of Gas Metal Arc Welding (GMAW). Conventional MIG welding typically operates in two primary modes of metal transfer:

- Short-Circuit Transfer: Characterized by the welding wire intermittently touching the weld puddle, causing a “short circuit” and extinguishing the arc.

- Advantages: Low heat input, suitable for thin materials, all-position welding.

- Disadvantages: Prone to spatter, potential for incomplete fusion (cold lap) on thicker materials, lower deposition rates.

- Spray Transfer: Achieved at higher voltages and wire feed speeds, where the molten metal transfers across the arc in a continuous stream of tiny droplets.

- Advantages: High deposition rates, deep penetration, minimal spatter, excellent fusion.

- Disadvantages: High heat input (risk of burn-through and distortion), typically restricted to flat and horizontal positions due to fluid puddle, not ideal for thin materials.

The dilemma for many fabricators was the absence of a process that offered the high-quality, spatter-free characteristics of spray transfer, coupled with the ability to weld out-of-position and on thinner materials without excessive heat. This critical gap paved the way for the development of Pulse MIG.

II. The Mechanics of Pulse MIG: Precision on Demand

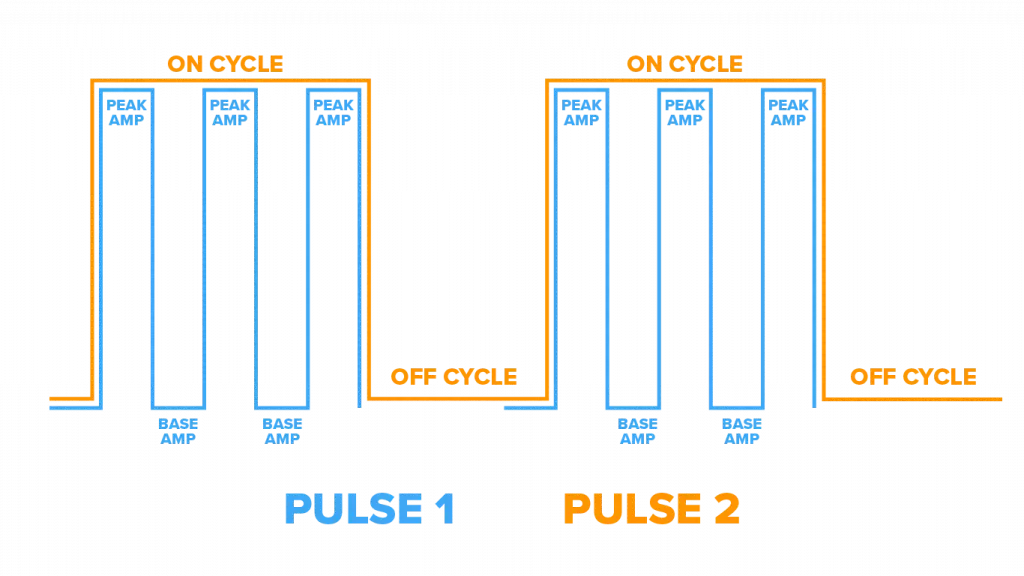

Pulse MIG welding represents an ingenious modification of the spray transfer process. Instead of a continuous high-current arc, Pulse MIG cycles between two distinct current levels: a high peak current and a low background current. This precise current modulation allows for superior control over the molten metal transfer and overall heat input.

The Pulsed Waveform Explained:

- Peak Current (Ip): During the peak current phase, the welding power supply momentarily ramps up to a high amperage. This high current is sufficient to precisely detach a single, fine droplet of molten metal from the wire tip and propel it across the arc to the weld puddle. This mimics the efficient transfer mechanism of conventional spray arc, but on a micro-scale.

- Role: Facilitates droplet detachment and ensures good fusion.

- Settings: Determines the force with which the droplet is projected, impacting penetration.

- Background Current (Ib): After the droplet detaches, the power quickly drops to a much lower background current. This low current is sufficient to maintain the arc and keep the wire tip preheating, but it provides insufficient energy to melt and transfer another droplet.

- Role: Allows the weld puddle to cool and solidify slightly between droplets, and controls overall heat input.

- Settings: Impacts puddle fluidity and solidification rate.

- Pulse Frequency (Hz): This parameter defines how many peak-background cycles occur per second. A higher frequency means more droplets are transferred per second.

- Influence: Affects the stability of the arc, the rhythm of droplet transfer, and the fluidity of the weld puddle. A higher frequency can result in a tighter arc cone and more aggressive penetration.

- Pulse Width (Duty Cycle) or Pulse On-Time: This is the duration of the peak current phase relative to the background current phase within a single pulse cycle.

- Influence: Longer peak-current duration allows more heat input per pulse, while a shorter peak-current duration reduces heat input. It affects droplet size and the amount of metal transferred with each pulse.

Synergic Control: Simplifying Sophistication

One of the most significant advancements facilitating the adoption of Pulse MIG is synergic control. In a synergic system, the welding machine’s power source comes pre-programmed with optimized waveforms and parameters for specific wire types, sizes, and shielding gases.

When the operator adjusts a single primary setting—typically the wire feed speed (which directly correlates to average amperage)—the synergic system automatically and intelligently adjusts all other relevant pulse parameters (peak current, background current, frequency, pulse width, etc.) to maintain a stable arc and optimal droplet transfer. This simplifies operation immensely, reducing the complex parameter adjustment typical of early pulse machines into a more intuitive, “one-knob” control system.

III. Unparalleled Advantages of Pulse MIG Welding

The controlled and rhythmic nature of metal transfer in Pulse MIG offers a multitude of benefits that elevate weld quality, extend versatility, and significantly boost productivity.

- Enhanced Puddle Control for All-Position Welding:

The key to Pulse MIG’s success. The brief, high-current peaks quickly transfer metal, and the subsequent drop to background current allows the weld puddle to cool and solidify slightly before the next droplet arrives. This “stiffening” effect makes the weld puddle less fluid and significantly easier to control in all positions—vertical up, vertical down, and overhead—something impossible with conventional spray transfer. This capability translates directly to increased efficiency, as welders no longer need to reposition parts or switch processes. - Reduced Heat Input and Minimal Distortion:

By rapidly cycling the current, Pulse MIG effectively limits the average heat input into the workpiece compared to conventional spray transfer. The brief bursts of peak current provide enough energy for fusion and droplet transfer, but the longer background current phase acts as a cooling period.- Benefits: Minimized heat-affected zone (HAZ), less material distortion, reduced risk of burn-through on thinner materials, and superior metallurgical properties for heat-sensitive alloys like stainless steel and aluminum. This is especially critical in industries where dimensional accuracy and material integrity are paramount.

- Virtually Spatter-Free Welding:

The precise and controlled detachment of a single droplet per pulse largely eliminates the short circuits and explosive droplet transfer common in short-circuit MIG, which are primary causes of spatter.- Benefits: Significant reduction in post-weld cleaning, leading to labor cost savings, improved aesthetic quality, and less wasted filler material.

- Wider Operating Window and Increased Material Versatility:

Pulse MIG extends the practical range of material thicknesses that can be welded effectively with a single process. It can handle very thin materials (often as thin as 16 gauge or less) without burn-through, while simultaneously possessing the penetration capabilities for medium to thick sections (up to 1 inch or more, depending on joint design). This versatility makes it ideal for shops working with a diverse array of projects and materials. - Higher Productivity and Deposition Rates:

Compared to GTAW, Pulse MIG offers significantly faster travel speeds and higher deposition rates, without sacrificing quality. While potentially not as fast as conventional spray transfer in flat positions, its ability to produce spray-quality welds in all positions means fewer setups, less rework, and overall higher throughput for complex assemblies. This is especially true when replacing GTAW on certain applications. - Improved Weld Quality and Mechanical Properties:

The precise arc control and cleaner transfer lead to welds with a smoother, more uniform bead profile, excellent tie-in at the toes, and consistent penetration. Reduced heat input also preserves the mechanical properties and corrosion resistance of heat-sensitive materials, preventing issues like “sugaring” in stainless steel or over-aging in aluminum. - Easier for Welders (with Synergic Control):

While earlier Pulse MIG machines required a significant learning curve, modern synergic systems have simplified operation considerably. Welders can often dial in settings by simply selecting the material, wire size, gas, and then adjusting a single control (usually wire feed speed) to find the sweet spot, making high-quality welding more accessible.

IV. Ideal Applications and Material Versatility

Pulse MIG truly shines when welding certain materials and in specific industrial applications where precision, heat control, and versatility are critical.

- Aluminum and Aluminum Alloys:

Pulse MIG is arguably the superior GMAW process for welding aluminum.- Challenges of Aluminum: High thermal conductivity (requires high heat to fuse but also dissipates heat rapidly), soft filler wire (prone to bird-nesting in traditional push-systems, necessitating push-pull guns), tendency for porosity from oxides and hydrogen.

- Pulse MIG’s Solution: The controlled spray transfer pierces surface oxides effectively and provides consistent heat, reducing porosity. The faster travel speeds minimize heat soak, controlling distortion and maintaining alloy properties. Its all-position capability is invaluable for large aluminum structures like boats, trailers, and aerospace components.

- Stainless Steel and High Nickel Alloys:

These materials are highly sensitive to heat, and excessive heat input can lead to:- “Sugaring” or “Carbide Precipitation”: Where chromium carbides form along grain boundaries, depleting chromium in those areas and significantly reducing corrosion resistance.

- Distortion: Due to high thermal expansion rates.

- Pulse MIG’s Solution: Low average heat input minimizes these risks, preserving the corrosion resistance and mechanical properties of the alloy. It produces bright, clean welds with minimal discoloration, making it excellent for food processing, pharmaceutical, and chemical industries.

- Thin Gauge Materials (Steel, Stainless Steel, Aluminum):

Conventional spray transfer is generally too hot for thin materials, leading to burn-through. Short-circuit MIG generates spatter and often lacks the fusion and aesthetic appeal required.- Pulse MIG’s Solution: Its precisely controlled heat allows for excellent fusion and penetration on thin sections without blow-through or excessive distortion, providing a spray-quality finish suitable for automotive bodywork, HVAC systems, and architectural panels.

- Out-of-Position Welding (Vertical Up/Down, Overhead):

The ability to maintain a manageable, relatively stiff weld puddle is a game-changer for fabricating large or complex structures that cannot be easily repositioned.- Applications: Shipbuilding, heavy equipment manufacturing, structural steel erection, pressure vessel fabrication, and any repair work on large immovable components.

- Robotic and Automated Welding:

The consistency and stability of the Pulse MIG arc make it an ideal choice for robotic welding applications. The predictable droplet transfer ensures uniform weld beads, even with high travel speeds, enhancing the precision and efficiency of automated systems.

V. Optimizing Pulse MIG Settings for Peak Performance

While synergic systems simplify the setup, understanding the role of each parameter allows for fine-tuning to achieve optimal results for specific materials and joint designs.

- Wire Feed Speed (WFS) / Amperage:

This is typically the primary control on synergic machines, directly affecting the average amperage and thus the overall heat input and deposition rate. Increase WFS for hotter, faster welds, decrease for cooler welds. - Arc Length / Voltage Trim:

Often presented as “Arc Length Trim” or “Voltage Trim” on synergic machines. This allows the operator to fine-tune the electrical stick-out and therefore the length and stiffness of the arc.- Higher Trim: A longer, softer arc; flatter bead, less penetration.

- Lower Trim: A shorter, stiffer, more focused arc; deeper penetration, narrower bead.

- Effect on Droplet: Influences when the droplet detaches. Too long an arc can lead to large, uncontrolled droplets.

- Inductance:

Controls the “stiffness” or “crispness” of the arc and the fluidity of the weld puddle, particularly during the transition from peak to background current.- Higher Inductance: Allows the arc to “linger” a bit longer during current drops, resulting in a more fluid puddle, wider and flatter bead, and better “wet-in” (smooth transition between the weld bead and the base metal). Also reduces spatter.

- Lower Inductance: Creates a stiffer, more focused arc, deeper penetration, narrower and often more convex bead, and can lead to a bit more spatter if too low.

- Importance: Crucial for managing puddle fluidity on stainless steel and for aesthetic bead control.

- Shielding Gas Selection:

Crucial for Pulse MIG, particularly for preventing porosity and achieving optimal transfer.- Aluminum: 100% Argon is most common for GTAW quality. Argon-Helium blends can increase heat input and penetration for thicker sections.

- Stainless Steel: Argon with 1-2% Oxygen or Argon with 1-2% CO2 is common. These additions stabilize the arc, improve wet-in, and provide a clean bead. Avoid higher CO2 levels as it leads to more heat and carbon pickup, reducing corrosion resistance.

- Mild Steel: 90% Argon / 10% CO2 (or 92/8, 98/2) is typical. The argon ensures spray transfer, while the small percentage of CO2 provides better bead profile and improved wet-in.

- Contact Tip to Work Distance (CTWD) / Stick-Out:

Maintains a consistent arc voltage and current, as resistance heating of the wire affects the melt rate. Longer stick-out increases resistance heating, potentially requiring adjustments to other parameters. Keep it consistent for stable operation.

Tips for Dialing in Settings:

- Start with Synergic Presets: Always begin with the machine’s recommended synergic program for your specific material, wire diameter, and gas.

- WFS as Primary: Adjust wire feed speed (amperage) to get your desired heat input and deposition.

- Arc Length Trim for Feel: Fine-tune arc length to optimize puddle fluidity, bead appearance, and minimize spatter.

- Inductance for Wet-in: Adjust inductance for optimal bead profile and smooth tie-in.

- Listen to the Arc: A good pulse arc has a distinct, consistent buzzing or humming sound, free from popping or erratic crackling.

- Observe the Puddle: Look for a manageable, wet-looking puddle that ties into the base metal smoothly.

- Test on Scrap: Always perform test welds on similar material and joint configurations before welding the actual workpiece.

VI. Challenges and Considerations

While incredibly powerful, Pulse MIG welding does come with certain considerations.

- Higher Initial Investment: Pulse-capable MIG welders are generally more expensive than conventional MIG machines due to the sophisticated inverter technology and processing power required for waveform control.

- Learning Curve: Although synergic systems simplify operation, mastering Pulse MIG still requires a deeper understanding of its principles and how different parameters interact, especially for manual adjustments on non-synergic systems or for advanced fine-tuning.

- Consumables: While standard MIG wires and gases are used, optimal performance may require specific types or sizes of wire for certain pulse waveforms. The cost of some inert gas blends (e.g., Argon-Helium) can be higher.

- Maintenance Complexity: The advanced electronics in pulse machines can be more complex to service than simpler transformer-based MIG welders.

- Not a Universal Panacea: While highly versatile, Pulse MIG is not the ideal process for every application. For very thick, flat position mild steel welds where maximum deposition at maximum travel speed is the only goal, conventional spray transfer might still be faster. For extremely precise, low-heat thin gauge welding, GTAW may sometimes still be preferred.

VII. Future Trends and Innovations in Pulse MIG

The journey of Pulse MIG welding is far from over. Ongoing advancements focus on enhancing its intelligence, user-friendliness, and capabilities:

- Adaptive Waveform Control: Systems that can sense changes in arc conditions (e.g., changes in stick-out, joint gaps) and adapt the pulse waveform in real-time to maintain stability and quality.

- Artificial Intelligence and Machine Learning: Integrating AI to further optimize synergic programs, predict optimal settings, and even assist in troubleshooting.

- Enhanced Multi-Process Integration: Combining Pulse MIG capabilities within advanced multi-process welders, offering greater versatility in a single machine.

- Remote Monitoring and Diagnostics: Enabling operators to monitor weld parameters, performance, and diagnose issues remotely, critical for automated production lines.

- Eco-Friendly Advancements: Continued development in power efficiency and reduced waste.

Conclusion: Embracing the Future of Fabrication

Pulse MIG welding has unequivocally revolutionized the capabilities of GMAW, offering unprecedented control, quality, and versatility. By providing the precision of spray transfer without its traditional positional and heat-input limitations, it empowers welders and fabricators to tackle a broader spectrum of materials and complex designs with superior results.

For any professional serious about achieving cleaner welds, minimizing post-weld processing, preventing distortion in delicate materials, or expanding their out-of-position capabilities, understanding and adopting Pulse MIG technology is no longer an option—it is a strategic imperative. As the industry continues to push the boundaries of design and manufacturing, Pulse MIG will remain at the forefront, ensuring that the welds holding our world together are stronger, cleaner, and more efficiently produced than ever before. Embrace this powerful technology, and unlock the next level of welding excellence.

Frequently Asked Questions (FAQs) About Pulse MIG Welding

1. What is the core difference between Pulse MIG and conventional MIG welding?

The core difference lies in how the welding current is delivered. Conventional MIG (short-circuit or spray) maintains a continuous arc or cycle. Pulse MIG, however, rapidly switches between a high “peak current” (which detaches a single molten droplet) and a low “background current” (which allows the puddle to cool slightly). This pulsed delivery provides significantly more control over metal transfer, leading to benefits like reduced heat input, minimal spatter, and the ability to weld in all positions with spray-quality results.

2. What are the biggest advantages of using Pulse MIG over other MIG modes?

The biggest advantages of Pulse MIG include:

- All-Position Spray Transfer: Achieves spray-quality welds in vertical-up, vertical-down, and overhead positions, which is impossible with conventional spray arc.

- Reduced Heat Input: Less distortion, ideal for thin materials and heat-sensitive alloys like aluminum and stainless steel, minimizing issues like burn-through or material degradation.

- Minimal Spatter: Precise droplet detachment virtually eliminates spatter, reducing post-weld cleanup time and material waste.

- Wider Operating Window: Greater flexibility in welding different material thicknesses with one process.

- Improved Weld Quality: Consistent, aesthetically pleasing beads with excellent fusion.

3. Is Pulse MIG difficult to learn for a beginner?

While earlier Pulse MIG machines had a steep learning curve due to numerous parameters, modern Pulse MIG welders, especially those with synergic control, are significantly easier for beginners to learn. Synergic systems automatically adjust most parameters when you select the material, wire size, gas, and adjust a single control (usually wire feed speed). However, fine-tuning and understanding the subtle effects of adjustments (like arc length trim and inductance) still require practice and experience to master.

4. What types of materials are best suited for Pulse MIG welding?

Pulse MIG is exceptionally well-suited for welding:

- Aluminum and its alloys: Overcomes issues like oxide contamination, heat input, and distortion.

- Stainless Steel: Minimizes “sugaring,” preserves corrosion resistance, and reduces distortion by controlling heat input.

- High Nickel Alloys (e.g., Inconel, Hastelloy): Manages the heat sensitivity of these expensive, high-performance materials.

- Thin Gauge Materials (Steel, Stainless Steel, Aluminum): Provides controlled fusion without burn-through, offering cleaner results than short-circuit.

5. Does Pulse MIG eliminate spatter entirely?

Pulse MIG significantly minimizes spatter by ensuring precise and controlled droplet detachment during the peak current phase. It virtually eliminates the short circuits that are the primary cause of spatter in short-circuit MIG. While it dramatically reduces spatter to very low levels, claiming 100% elimination in all scenarios might be an overstatement due to factors like material cleanliness, operator technique, or sub-optimal settings. However, it offers a remarkably cleaner welding experience compared to traditional MIG.

6. Is the higher cost of a Pulse MIG machine justified?

The higher initial investment for a Pulse MIG machine is often justified by the significant long-term benefits and increased capabilities. It offers:

- Increased Productivity: Faster welding of certain materials and processes, reduced post-weld cleanup.

- Superior Quality: Cleaner welds, better mechanical properties, reduced distortion.

- Greater Versatility: The ability to weld more materials and in all positions with one machine, reducing the need for multiple welding processes.

- Reduced Rework: Fewer defects and re-welds due to better control.

For shops dealing with aluminum, stainless steel, thin materials, or out-of-position work, the gains in efficiency, quality, and material savings often lead to a rapid return on investment, making it a valuable asset despite the higher upfront cost.