We have been discussing different types of arc welding in the previous article. Yes, this TIG welding is one of the types of Arc welding. The full form of TIG welding is Tungsten Inert gas Welding. Let us discuss more details such as the TIG welding process, TIG welding used for which applications, and TIG welding advantages and disadvantages.

Tungsten Inert gas Welding(TIG)

Tungsten Inert gas Welding(TIG) is also known as Gas Tungsten Arc Welding (GTAW). TIG welding is one of the most popular methods used for high-quality welds. In this Tungsten Inert gas welding, we use a non-consumable electrode and shielding gas to protect the oxidation.

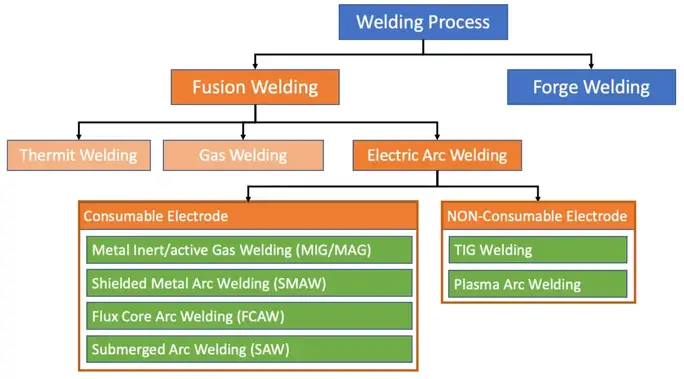

Following is the overall classification of the Welding process.

Tungsten inert gas welding is classified under the Electric arc welding process with the non-consumable electrode.

Tungsten Inert gas Welding(TIG) Process

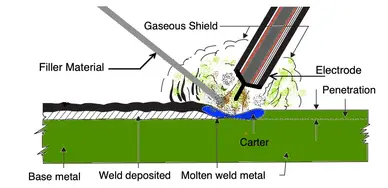

This Tungsten inert gas welding is for high-quality welds, it also requires a skilled welder. Since constantly maintaining the short ar between the electrode and workpiece (The contact between the workpiece and the electrode must be prevented)with one hand and with the other hand the filler material needs to be supplied in coordination with the arc. This requires a highly skilled welder.

- In order to strike the arc in this TIG welding process, a high frequency generator provides the electric spark.

- This electric spark is a conductive path for the welding current through the shielding gas and allows the arc to be initiated.

- When the torch (electrode) and the workpiece are brought together, by a close distance of 1.5mm to 3mm the (They should not come in contact, this is important)

- Once the arc is produced, the welder must need to create a weld pool by slowly moving the torch in a circular path while maintaining the same separation distance of 1.5mm to 3mm.

- The size of the weld pool will be based on the electrode size and the amount of welding current passing.

- This weld pool is created y the base metal.

- Now the torch needed to be slightly tilted and the filler metal should be added at the front end of the weld pool as needed.

- This process continued in the welding requirement areas.

Often, Professional welders use a special technique to avoid the oxidation of the filler material and contamination of the weld by rapidly alternating between moving the torch forward and adding filler metal.

This also helps us to avoid the melting of the filler rod before it contacts the weld puddle. This usually happens with filler rods made of aluminum. The filler rod made of aluminum has a very low melting temperature and that requires that the operator should maintain some distance from the arc while keeping the filler rod inside the gas shield.

Electrodes used in TIG Welding

- Pure Tungsten (with a 1 to 4% thoria added to improve arc ignition or zirconia addition is used to reduce electrode erosion)

- Lanthanum oxide (Better starting arc performance)

- Cerium oxide (Also have better Arc performance similar to Lanthanum)

Gases used in TIG Welding

- Argon – the most commonly used shielding gas in TIG welding. Argon added with a 2% to 5% H2 (hydrogen) will make the gas slightly reducing, will produce a cleaner-looking welds without surface oxidation. It also allows high welding speeds due to arc is hotter and more constricted. But there is one drawback if we use hydrogen. That is the risk of hydrogen cracking in carbon steels and weld metal porosity in aluminum alloys.

- Helium and helium/argon mixtures – We can raise the temperature of the arc by simply adding the helium to argon. This promotes higher welding speeds and deeper weld penetration. The only drawback is that, using helium or a helium/argon mixture is a high cost for the gas and the starting of the arc is slow and difficult.

What materials we can weld with TIG Welding?

TIG welding can be used for welding a wide range of materials including Aluminum, magnesium, steel, stainless steel, and titanium. Filler materials are available based on the type of materials you wanted to weld.

TIG welding Applications

- Aerospace industry

- Marine

- Bicycle industry

- Piping systems

- Repair work for the tools and dies which are made of aluminum Magnesium

TIG welding is suitable for all industries, but just because of its high-quality welds and the requirement of skilled welders, it has been used for the application where we really need quality weld with more control during the welding operation.

Advantages of TIG Welding

- It offers Greater controll of welding operating

- Clean and aesthetically pleasing welds

- Produce strong welds as parent material strength

Disadvantages of TIG Welding Operating

- Complex process

- Slow when compared to MIG welding

- Require highly skilled Welder

- Takes longer lead times and greater production costs

Conclusion

We have discussed the TIG welding process, and where the TIG welding process used, and what are the applications, advantages of TIG welding also disadvantages of the TIG welding process. Most importantly what is the electrode materials used in TIG welding and the gaseous used in TIG welding. Let us know what do you think about this article in the comment section below.

Compare this TIG welding with MIG welding here!

![Welding vs. Brazing vs. Soldering [ What is the main difference ] 2 Welding vs. Brazing vs. Soldering [ What is the main difference ]](https://www.021208.com/wp-content/uploads/2024/05/welding-1-150x150.jpg)