Start by understanding the basics of stick welding. With practice and the right techniques, you can achieve high-quality welds. In this article, we will discuss nine valuable tips and tricks to enhance your stick welding skills. Let’s dive in!

Stick welding, while not the hardest to learn, can still be difficult at times. If you’re looking to improve your welding, give these tips and tricks a try.

021208.com

1. Select the Right Electrode

Choosing the appropriate electrode is crucial for successful stick welding. Consider the type of metal you are welding and its thickness. Different electrodes have unique properties and are suitable for specific applications. For example, E6010 electrodes are ideal for deep penetration, while E7018 electrodes provide excellent strength and durability.

2. Prepare the Welding Surface

Prepare the welding surface before starting the process. Remove any rust, paint, or debris from the metal using a wire brush or grinder. Cleanliness is essential for achieving strong and durable welds. Additionally, ensure proper grounding to minimize electrical interference during welding.

3. Maintain Proper Arc Length

Maintaining the correct arc length is crucial for achieving optimal results. Keep the arc length between 1/8 to 3/16 of an inch (3-5mm) for most stick welding applications. This distance ensures proper heat control and reduces the chances of the electrode sticking or the weld spattering.

4. Control Your Travel Speed

Controlling your travel speed is vital to maintain a consistent weld bead. Moving too quickly can result in a weak and inadequate weld, while moving too slowly can cause excessive heat buildup and distortion. Practice maintaining a steady pace to achieve optimal results.

5. Angle and Direction

Pay attention to your welding angle and direction. For most applications, a slight drag angle works best, where the electrode is pointed towards the direction of travel. This angle ensures better penetration and reduces the risk of undercutting.

6. Use Proper Protective Gear

Safety should always be a top priority during stick welding. Wear appropriate protective gear, including a welding helmet, gloves, long-sleeved clothing, and welding boots. Protecting yourself from sparks, UV radiation, and potential hazards is essential for a safe and productive welding experience.

7. Practice Proper Joint Preparation

Before welding, ensure proper joint preparation. Clean and bevel the edges to create a suitable groove for the weld. Proper joint design and fit-up are crucial for achieving strong and visually appealing welds.

8. Manage Your Amperage Settings

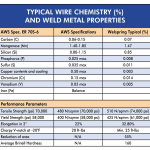

Controlling the amperage settings on your welding machine is vital for stick welding. Adjust the amperage based on the electrode diameter, material thickness, and welding position. Refer to the electrode manufacturer’s guidelines and practice to find the optimal settings for your specific welding projects.

9. Post-Weld Cleaning and Inspection

After completing a weld, it is essential to perform post-weld cleaning and inspection. Remove any slag or spatter using a chipping hammer or wire brush. Inspect the weld for defects such as cracks, porosity, or insufficient penetration. This step ensures the quality and integrity of your welds.

Conclusion

Stick welding can be a rewarding skill to master, and with these nine tips and tricks, you can significantly improve your welding results. Remember to select the right electrode, prepare the welding surface properly, control your arc length and travel speed, pay attention to angles and directions, prioritize safety, practice joint preparation, manage your amperage settings, and perform post-weld cleaning and inspection. By following these guidelines, you’ll be well on your way to achieving high-quality stick welds.

FAQs

Q1: Can I use stick welding for all types of metals? Yes, stick welding can be used on various metals, including steel, stainless steel, cast iron, and more. However, it is important to select the appropriate electrode for each metal type.

Q2: How do I determine the correct amperage for stick welding? The amperage setting depends on factors such as electrode diameter, metal thickness, and welding position. Consult the electrode manufacturer’s guidelines and practice to find the optimal amperage for your specific welding project.

Q3: Is stick welding suitable for beginners? Stick welding can be challenging for beginners due to its technical aspects. However, with practice and proper guidance, beginners can learn and excel in stick welding.

Q4: How do I prevent electrode sticking during stick welding? Maintaining the correct arc length and using the appropriate electrode can help prevent electrode sticking. Additionally, adjusting the amperage settings and controlling travel speed can contribute to smoother welding.

Q5: Can I weld in outdoor conditions with stick welding? Yes, stick welding is suitable for outdoor conditions as it is less affected by wind compared to other welding processes. However, it is important to take necessary precautions and ensure proper grounding for safety.