This article provides a comprehensive introduction to welding robots in terms of safe operating procedures, maintenance methods, fault response, maintenance cycle, productivity improvement, common failure solutions, industry applications, selection recommendations, programming and debugging skills required and posting of safety regulations. Mastering these knowledge and skills will help to better utilize welding robots, improve productivity and quality, and ensure production safety.

Guide to Welding Robots

Welding Town

1. Welding Robot Safety Regulations

Welding robot safety regulations are a series of specific steps and precautions developed to ensure the personal safety of the operator, the normal operation of the equipment and the smooth progress of the production process when using welding robots for operations.

Welding robot safety procedures include the following:

1. The robot must be tested before work: check the wire channel, wire is not broken leakage; robot body, external axis, clean gun station, water cooler, etc. is strictly prohibited to place sundries, tools, etc.; control cabinet is strictly prohibited to place the liquid objects (such as bottles, etc.); there is no leakage of air and water leakage of electricity; welding tooling threads are not damaged, whether there is no abnormality of the robot.

2. The robot can be operated only when there is no alarm after the power is turned on. After the use of the teaching box, it should be placed in the specified position, away from the high temperature area, and should not be placed in the working area of the robot in order to prevent collision.

3. Before operation, check whether the voltage, air pressure, indicator display is normal, whether the mold is correct, and whether the workpiece is installed in place. Always wear working clothes, working gloves, working shoes and protective glasses when operating. The operator must operate carefully to prevent collision accidents.

4. Equipment abnormalities or malfunctions found during operation should be stopped immediately to protect the site and then reported for repair. It is necessary to stop the machine before entering the robot operation area to adjust or repair.

5. After welding finished parts, check for uncleaned spatter burrs in the nozzle and bent welding wire, and clean them when necessary. Keep the gun station oil injection emitter free of clogging and oil in the oil bottle.

6. Robot operators must be qualified and licensed. Entering the training site should follow the arrangements of the instructor, safe dress, listen carefully, observe carefully, strictly prohibit playfulness and keep the site clean and tidy.

7. Operate carefully and meticulously to prevent collision accidents. Non-professionals are strictly prohibited from entering the robot work area.

8. After the work is completed, close the gas line device, cut off the power supply of the equipment, to confirm that the equipment has stopped, in order to carry out cleaning and maintenance.

In addition, there are a number of safety rules to follow, such as the operator must be professionally trained and familiar with the most basic knowledge of equipment safety; open the valve switch to ensure that the air pressure between the prescribed range; prohibit unrelated personnel to enter the robot workplace; equipment automatic operation, prohibit the approach to the scope of activities of the robot and so on.

The above information is for reference only. Specific safety operation procedures may vary depending on the robot model, usage environment, etc. Therefore, in actual operation, you should refer to the robot’s instruction manual and safety operation procedures, and strictly observe the relevant regulations.

2. how to maintain the robot

Robot maintenance is key to ensuring its long-term stable operation. Different types of robots (e.g., industrial robots, service robots, domestic robots, etc.) may require different maintenance strategies, but here are some general robot maintenance recommendations:

1. Read the manual: Before performing any maintenance, always read the robot’s owner’s manual and maintenance guide carefully for the manufacturer’s specific recommendations and requirements.

2. Periodic Inspection: Conduct periodic inspections in accordance with the manufacturer’s recommended cycles, including mechanical components, electrical systems, and software.

3. Cleaning: Keep the robot clean to avoid accumulation of dust, dirt, and debris, which may affect the performance and life of the robot. Gently wipe the enclosure and visible parts with a clean cloth or appropriate cleaner.

4. Lubrication: Lubricate moveable parts as needed to minimize wear and maintain smooth movement. Use lubricants recommended by the manufacturer.

5. Battery Maintenance: If the robot uses batteries, make sure they are charged and discharged correctly to avoid overcharging or overdischarging, which can damage them.

6. Software updates: Regularly check for and install software updates to ensure that the robot is running the latest operating system and security patches.

7. Parts Replacement: Replace worn or damaged parts in a timely manner to avoid causing greater problems.

8. Environmental control: Ensure that the ambient temperature, humidity and dust levels in which the robot operates are within permissible limits.

9. Professional maintenance: For complex robotic systems, regular inspection and maintenance by specialized technicians may be required.

10. Avoid misuse: Ensure that the robot is not overused or used for purposes for which it was not designed, which could lead to premature wear and tear.

11. Train operators: Ensure that all operators are properly trained in the proper use and maintenance of the robot.

12. Record maintenance: Establish a maintenance log to record the date and content of each maintenance and any problems found.

13. Emergency procedures: Develop and familiarize yourself with emergency operating procedures so that you can respond quickly if problems arise.

14. Storage: If the robot is not to be used for an extended period of time, it should be stored appropriately in accordance with the manufacturer’s instructions to prevent degradation of the components.

By following the maintenance recommendations above, you can extend the life of your robot, reduce the likelihood of malfunctions, and maintain its optimal performance. Remember, the frequency and specific steps of maintenance should be adapted to the type and use of the robot.

3. What should I do if the robot breaks down or has an accident during operation?

In the event of a malfunction or accident with the robot during operation, here are some suggestions:

1. Record the abnormal situation: Keep calm and record the status of the robot, alarm messages, program backup Logfile and other key information at the time of failure.

2. Preliminary diagnosis: Try to make a preliminary judgment based on the observed phenomena to distinguish whether the problem is a mechanical or electrical failure. You can refer to the robot’s electrical and mechanical drawings and related manuals to assist in troubleshooting.

3. System reboot: Sometimes a simple reboot can solve the problem. Power off the robot and wait for some time before turning it back on to make sure the system is fully reset.

4. Check the connection: Check whether the robot host is working properly, whether the built-in memory card (e.g. SD card) is faulty, and whether the network connection between the demonstrator and the host is loose or disconnected.

5. Analyze the schematic diagram: Analyze the electrical schematic diagram and the wiring diagram of the mechanical unit, and if necessary, conduct real-time monitoring of the PLC program as well as the robot’s execution position in order to lock the scope of the problem point.

6. Part replacement: If possible, try to check if the problem is solved by replacing the suspected identical part.

7. Professional technical support: If the above steps do not solve the problem, you should contact the manufacturer’s customer service or technical support department for professional technical advice and assistance.

8. Safety First: Throughout the process, ensure that all safety procedures are followed to avoid personal injury or further equipment damage.

9. Failure prevention: In order to minimize the probability of failures, it is very important that the robot be serviced and maintained on a regular basis. Also, ensure that all operators are properly trained to be able to handle unexpected situations correctly.

10. Failure analysis: Understand the common types of failures and their solutions so that you can take quick action when problems occur.

Overall, when faced with a malfunction or accident during robot operation, it is important to remain calm and follow the correct procedures and methods for troubleshooting and handling.

4. the maintenance cycle and method of welding robot?

Maintenance intervals and methods for welding robots vary depending on the equipment and usage, but typically include daily, weekly and monthly inspections and maintenance.

First of all, daily maintenance is basic and essential, and consists of the following aspects:

1. Wire feeding mechanism check: make sure that the distance between the wire feeding force is normal, the wire feeding conduit is not damaged, and there is no abnormal alarm.

2. Gas flow check: gas flow needs to be kept normal to ensure welding quality.

3. Welding torch safety protection system check: the anti-collision system must operate normally and the welding torch safety protection function must not be turned off.

4. Cooling water circulation system check: confirm whether the cooling system is working properly.

5. TCP (Tool Center Point) Check: Test whether TCP is working properly.

Next, weekly maintenance is much more detailed, requiring in-depth inspections and cleaning of all parts of the robot:

1. Clean the robot body axes: Wipe the robot axes to remove dust and splatters.

2. Check the accuracy of TCP: Ensure the accuracy of TCP to avoid welding deviation.

3. Check the zero position accuracy: Confirm whether the zero position of each axis is accurate.

4. Clean the cooling water circulation system filter: keep the cooling system clean to avoid clogging.

5. Clean the compressed air intake filter: ensure a clean air supply.

6. Clean the torch nozzle and wire feeding mechanism: keep the torch and wire feeding mechanism clean to ensure the welding effect.

7. Inspect the hose bundle and guide hose: make sure there are no tears or breaks.

8. Check external emergency stop buttons and safety collision avoidance systems: Ensure that safety features are functioning properly.

Finally, monthly maintenance entails a thorough check of the overall performance and safety of the robot. This may include, but is not limited to:

1. Comprehensively inspect and test the robot’s welding system: ensure the stability and reliability of the welding system.

2. Check for loose screws in each axis of the robot: tighten any parts that may be loose.

3. Comprehensive inspection of the welding environment: Ensure that the welding operation is in a stable environment, away from large machinery that may cause vibration.

When carrying out maintenance, the operator should be responsible for recording each maintenance, and report to the maintenance personnel in a timely manner in the event of equipment failure, describing in detail the condition of the equipment before the failure and the operation process, so that production can be resumed as soon as possible. Such maintenance not only extends the service life of the robot, but also improves the efficiency of the enterprise.

5. How to improve the productivity of welding robots?

Increasing the productivity of a welding robot involves optimization and improvement in several areas. Here are some key points that can help improve the productivity of your welding robot:

1. Program Optimization: Ensure that the weld program is optimized to reduce unnecessary movement and waiting times. Using efficient path planning and weld sequencing can reduce weld cycle times.

2. Preventive Maintenance: Preventive maintenance is performed on a regular basis to minimize equipment failures and downtime. This includes regular inspections and maintenance of robots, torches, cables and other critical components.

3. Equipment upgrades: Upgrade to higher performance robots and welding equipment to improve welding speed and quality. For example, use higher precision robots and faster welding techniques.

4. Process optimization: Optimize welding parameters such as current, voltage, welding speed and shielding gas flow rate to improve welding quality and reduce defect rate.

5. Operator Training: Ongoing training is provided to operators and maintenance personnel to ensure that they are up to date with the latest welding technology and robot operation techniques.

6. Automated material handling: integrated automatic loading and unloading system reduces the time for manual loading and unloading of workpieces and realizes continuous production.

7. Data analysis: Collect and analyze production data in order to identify bottlenecks and improvement points. Using data analysis tools can help monitor productivity and predict potential equipment failures.

8. Flexible Programming: Easy to program and reconfigure software is used in order to quickly adapt to different welding tasks and the production of new products.

9. Integrated Sensor and Feedback System: Integrated advanced sensor and feedback system to monitor the welding process in real time and automatically adjust parameters to maintain high quality welding results.

10. Reduced production interruptions: Reduce production interruptions due to material shortages or replacement welding tasks through better production planning and inventory management.

11. Standardized Operating Procedures: Establish standardized operating procedures and work instructions to ensure that each operational step can be efficiently executed.

12. Improve the working environment: Ensure that the robot is working in a suitable environment, including proper temperature and humidity control and good lighting, which will help to improve operational efficiency and reduce errors.

Through these measures, the productivity of welding robots can be significantly increased and production costs can be reduced while ensuring weld quality.

6. welding robot common faults and solutions?

Common failures and solutions that may occur during the use of a welding robot include, but are not limited to, the following:

1. Power supply problems

○Reason for failure: unstable power supply voltage or problems with the power supply line.

○Solution: Ensure that the power supply system is stable and use a voltage regulator; check and repair the power cord connection to ensure good contact.

2. Welding deviation or inaccurate position

○Cause of malfunction: Deviation in workpiece assembly, inaccurate setting of TCP (Tool Center Point).

○Solution: Re-check and correct workpiece assembly accuracy; adjust and update TCP parameters to ensure accurate torch positioning.

3. Collision of guns

○Cause of malfunction: Programming path error, sensor failure, or change in workpiece clamping position.

○Solution: Re-taught or modified the program to avoid collision; checked and repaired or replaced the sensor; strengthened the stability of workpiece positioning.

4. Arc faults (inability to initiate an arc)

○Cause of failure: no contact between the wire and the workpiece, too low welding current, insufficient supply of shielding gas, or wear and tear of the wire conductive nozzle.

○Solution: Make sure that the wire contacts the workpiece correctly; adjust the welding process parameters such as current and voltage; check the gas circuit system to ensure that the gas flow is sufficient; and replace the worn conductive nozzle in time.

5. Welding defects

○ Such as biting edges, air holes, cracks, excessive splashing, etc.

○Solution: Adjust the welding parameters according to the specific type of defect, such as current size, welding speed, gas flow rate, etc.; improve the welding process, such as changing the welding sequence, increasing the preheating process or adopting suitable filler materials; clean up the oil and rust in the weld area to ensure a good welding environment.

6. Failure of mechanical components

○ Such as poor lubrication of motors, gearboxes, shaft joints, and damage to transmission parts.

○Solution: Perform regular mechanical maintenance, including cleaning, lubrication, and replacement of worn parts; inspect parts with abnormal sound or vibration, and have them repaired or replaced by professionals when necessary.

7. Control system failure

○ Such as controller crash, communication interruption, software error, etc.

○Solution: Restart the device, restore factory settings or update the software version; check whether the hardware interface connection is firm and whether the cable is broken; contact the manufacturer’s technical support for a solution.

In summary, the key to troubleshooting welding robots is to use a combination of specialized knowledge and technical skills to find the problem at the source and take appropriate preventive and maintenance measures, while following the guidance and recommendations in the equipment’s operating manual. For complex faults, the support and assistance of a specialized technical team may be required.

7. In which industries are welding robots widely used?

Welding robots are widely used in a variety of industries, especially in those areas where productivity, product quality and safety in the work environment are important. The following are some of the more widely used industries for welding robots:

1. Automotive manufacturing industry: welding robots are particularly used in the automotive industry, including but not limited to body welding, parts manufacturing and other links. Spot welding robots are commonly used in automobile production line body assembly, to ensure high precision and consistency in mass production.

2. Aerospace industry: aircraft, rockets, satellites and other equipment manufacturing process involves a large number of complex welding tasks, such as aluminum alloys, titanium alloys and other materials, precision welding, requires high precision and high quality welding robot to complete.

3. Rail transportation: The manufacturing of rail vehicles also relies on the efficient and stable operation of welding robots, including the assembly and welding of structural parts of carriages.

4. Heavy machinery and steel structure: including ships, bridges, building steel structure and other fields, welding robots can effectively deal with the welding challenges of large parts, improve work efficiency and ensure structural stability.

5. Electrical and electronic industry: small precision electronic components and connectors welding, as well as complex circuit boards on the realization of the fine welding process, may be with the help of welding robots to improve accuracy and reliability.

6. Medical Devices: High-quality medical equipment, such as X-ray machines, CT scanners and other internal structures, welding robots can accurately perform welding operations to ensure product safety and durability.

7. Energy equipment: for example, nuclear power plant pressure vessels, wind turbine towers and other energy facilities in the manufacturing process, welding robots undertake the welding of key components.

8. Household appliances and other metal products industry: refrigerators, washing machines and other home appliances shell and internal components welding, as well as other metal furniture, toolboxes and other products are also widely used in the production of welding robots.

In short, welding robots play an important role in various industries that require welding of metallic or non-metallic materials due to their excellent automation and intelligence features. With the development of technology, its scope of application is still expanding.

8. how to choose the right welding robot

There are several aspects to consider when choosing the right welding robot:

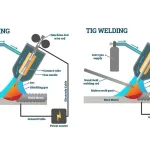

1. Welding type: First determine the type of welding you need to perform, such as MIG/MAG welding, TIG welding, resistance welding, laser welding and so on. Different types of welding require different welding equipment and robots.

2. Workpiece size and shape: Consider the maximum size, shape and weight of your workpiece, which will determine how much working range and load capacity you need from your robot.

3. Welding process requirements: According to your requirements for welding quality, speed and precision, choose a welding robot that can meet your needs. For example, some robots are suitable for high-speed welding, while others are more suitable for high-precision welding.

4. Production environment and conditions: Consider the temperature, humidity, dust, light and other conditions of your production environment and choose a robot that can adapt to these conditions.

5. Accessibility and Path Planning: Ensure that the selected robot has sufficient accessibility to all locations of the workpiece to be welded. It is also important that the robot’s path planning capability should be able to automatically plan the optimal welding path.

6. System integration: If your production line has other equipment or systems, you need to consider whether the robot can seamlessly integrate with them.

7. Safety performance: Ensure that the selected robot has good safety protection performance, and can protect the safety of the operator and the surrounding environment.

8. Budget and maintenance: Finally, consider the budget for purchasing and maintaining the robot. The price of different models and brands of robots varies greatly, and the choice should be weighed against your affordability.

9. After-sales service and technical support: choose a robot brand with good after-sales service and technical support, so that you can get timely solutions and support when you encounter problems during use.

It is recommended that before purchasing, it is best to consult with a professional welding robot supplier or integrator who can provide professional advice and solutions based on your specific needs.

9. What skills and knowledge are required to program and commission a welding robot?

Programming and commissioning of welding robots requires the following skills and knowledge:

1. Robot control related knowledge: the operator needs to be familiar with the programming and workflow of the welding robot, understand the structure of the welding robot, and have robot control related work experience.

2. Knowledge of welding techniques: Operators need to understand the different types of welding methods, the position and shape of welds, and the welding materials used.

3. Programming language skills: Programmers need to be proficient in a specialized robot programming language such as Robotic Programming Language (RPL) or Robot Programming for Arc Welding (RPAW).

4. Path planning and motion control skills: Engineers need to determine the optimal path for welding welds, as well as the trajectory and speed of the robot’s motion, to ensure quality and consistency of the weld.

5. Welding parameter setting skills: Engineers need to define welding current, voltage, speed and other key parameters to ensure stability and consistency in the welding process.

6. Simulation and debugging skills: Programmers need to use virtual environments to test the accuracy and effectiveness of programming, identify potential problems and make necessary adjustments.

7. Troubleshooting skills: The operator needs to be able to press the emergency stop button in time to prevent accidents in the event of a malfunction, such as unstable welding speed or incorrect welding direction.

8. Quality Awareness: Operators need to have quality awareness to ensure that the welding quality meets the standards and to fine-tune the welding process.

9. Adaptability and flexibility: debugging workers need to be adaptable and flexible, able to respond flexibly according to the specifications of the workpiece, debugging for different workpieces.

10. Continuous learning and skills upgrading: Operators need to continue to learn and improve their skills level in order to be able to solve problems arising from welding robots and improve productivity.

In conclusion, the programming and commissioning of welding robots requires operators with a wealth of skills and experience to ensure the proper operation of welding robots and product quality.

10. Does the welding robot’s safety procedure need to be posted at the work site?

Yes, the welding robot’s safe operating procedures should be posted in a conspicuous location on the job site. According to safety regulations and standards, the safety procedures for all operating equipment should be readily accessible to employees so that operators can understand and comply with the relevant safety regulations before performing the work. Placing the procedures at the work site can remind employees to pay attention to safety matters at all times and prevent safety accidents caused by negligence or unfamiliarity with the operating procedures. In addition, it helps supervisors to confirm that the company is following the procedures during inspections, and to provide timely guidance and training to employees when needed. It is therefore important to ensure that welding robot safety procedures are visible, easy to read and up to date.

The following are some of the things that may be included in a welding robot safety procedure:

1. Personal Protective Equipment (PPE): Staff are required to wear appropriate PPE when operating the robot, such as dust masks, protective eyewear, earplugs, anti-static suits, insulated gloves, etc.

2. Operator training: Ensure that all operators have received appropriate training and are able to understand operating procedures and safety protocols.

3. Start and Stop Procedures: Detailed instructions on how to safely start and stop the welding robot, including the location and use of the emergency stop button.

4. Maintenance and overhaul: Provides guidelines for the maintenance and overhaul of robots and related equipment, as well as safety measures to be followed during these operations.

5. Contingency plan: List possible emergencies and their response, including fire, robot failure, electrical failure, etc.

6. Safety inspections: Provide for a schedule of periodic safety inspections and what areas are to be inspected, such as sensors, limiters, and emergency stops.

7. Requirements for the working environment: state the conditions that should be met by the robot’s working environment, such as ventilation, temperature, humidity and cleanliness.

8. Prohibited Behavior: It is clearly stated which behaviors are prohibited to prevent accidents, e.g., it is prohibited to enter the work area of the robot while it is running.

Posting safety procedures helps to reduce the risk of accidents and injuries by reminding staff of safety and ensuring that they follow the correct procedures when operating welding robots. In addition, regular safety training and supervision are important measures to ensure safe operation.

The above content describes in detail the welding robot application industry, selection methods, programming and debugging skills, safety operation procedures, maintenance cycles and methods, productivity enhancement, common failures and solutions. With this knowledge, readers can better understand the operation, maintenance and application of welding robots, bringing higher efficiency and safety to enterprise production.