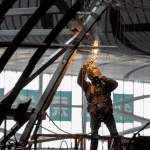

Aluminium Welding is the process of welding aluminium alloy materials. Aluminium alloys are strong and light in mass. The main welding processes are manual TIG welding (non-melting electrode inert gas shielded welding), automatic TIG welding and MIG welding (melting electrode inert gas shielded welding) with base material, welding wire, shielding gas and welding equipment.

Aluminum alloys are strong and light. The main welding processes are manual MIG welding (melting electrode inert gas shielded welding) and automatic MIG welding with base material, welding wire, shielding gas, and welding equipment.

WeldingTown

Aluminium and aluminium alloys occupy a pivotal position among the various materials used in modern engineering and technology, ranking second only to steel and first among non-ferrous metals in the world in terms of annual production [1]. If aluminium alloys first came to prominence in the aviation industry, then in recent decades, in addition to the aviation industry, aluminium and aluminium alloys have been used in large numbers in aerospace, automotive, shipping, bridges, mechanical engineering, electrical and chemical industries and cryogenic devices to manufacture various components, fuel tanks, corrosion-resistant containers and wires. The most widely used aluminium alloy welding structures are currently rust-proof aluminium alloys, i.e. aluminium-magnesium and aluminium-manganese alloys.

Aluminium alloy welding refers to the welding process of aluminium alloy materials.

Aluminium alloys are strong and light. The main welding processes are manual MIG welding (melting electrode inert gas shielded welding) and automatic MIG welding with base material, welding wire, shielding gas, and welding equipment.

Aluminium welding methods

1、Tungsten arc welding

The tungsten arc welding method is mainly used for aluminium alloy and is a better welding method, however, the tungsten arc welding equipment is more complicated and is not suitable for operation in open-air conditions.

2、Resistance spot welding, seam welding

This welding method can be used to weld thin aluminium alloy plates with a thickness of 5mm or less. However, the equipment used in welding is more complicated, the welding current is high and the productivity is high, especially for mass production of parts and components.

3、Pulse Argon Arc Welding

Pulsed argon arc welding can be very good to improve the stability of the welding process and can adjust the parameters to control the arc power and weld seam formation. Small deformation of the welded parts, small heat-affected zone, especially for thin plates, all-position welding and other occasions, as well as the heat-sensitive forged aluminium, hard aluminium, and super-hard aluminium welding.

4、Friction stir welding

The most important feature of this method is that the welding temperature is lower than the melting point of the material, which can avoid defects such as cracking and porosity brought about by fusion welding.

Aluminium welding environment material

(1) Requirements for production and storage temperature and humidity

The production and storage environment for aluminium alloys must be dustproof, waterproof and dry. The ambient temperature is usually controlled above 5 °C and the humidity below 70 %. The humidity in the welding environment should be kept as low as possible. Excessive humidity will significantly increase the chance of porosity in the weld seam, thus compromising the quality of the weld. The violent flow of air can cause inadequate gas protection, thus producing welding porosity, and can be set up to avoid the influence of indoor wind.

(2) Requirements for the use of welding wire and gas supply hoses

Attention should be paid to the use of welding consumables: aluminium welding wire should be stored separately from steel welding consumables and should not be used for more than 1a. After welding, the wire should be removed from the welding machine and sealed to prevent contamination. The ability of the gas supply hose to resist the entry of moisture varies from material to material, especially when the gas supply pressure is high. It is best to use Teflon hoses.

Choice of tooling

It is best to use point contact tooling for aluminium welding to reduce the contact area between the tooling and the workpiece. If the tooling is in contact with the workpiece, it will quickly take away the heat from the workpiece, accelerating the solidification of the molten pool, which is not conducive to the exclusion of the weld pores. The pressure of the workpiece hydraulic system is best controlled at 9 to 9.5 MPa.

The pressure is too small to achieve the purpose of preset anti-deformation, but the pressure is too large, and it will make the aluminium alloy structure more constrained. Due to the large coefficient of linear expansion of aluminium alloy and poor plasticity at high temperatures, large thermal stresses are easily generated during welding, which may cause cracks in the aluminium alloy structure.

Selection of welding wire

For 6005A, 6082 and 5083 base materials, the wire grade selected is 5087/ AlMg4.5MnZr. 5087 wire not only has good crack resistance, and superior porosity resistance but also has good strength properties. For the selection of wire specifications, priority is given to large-diameter wire. The same amount of welding filler that is the same weight of wire, large specifications than small specifications of wire surface area to be much smaller, therefore, large specifications of wire than small specifications of wire surface contamination to be less than the oxidation area to be small, welding quality is easier to meet the requirements. In addition, the wire feeding process for large-diameter wire is easier to handle. For the base material below 8mm plate thickness 1.2mm diameter wire is generally used, for 8mm and above plate thickness 1.6mm diameter wire is used. Automatic welding machines use 1.6mm diameter wire.

Selection of shielding gas

Ar100% is characterised by a stable arc and easy arc initiation and is generally used for welding base materials up to 8mm plate thickness. For base materials with a plate thickness of 8mm and above and for welds with high porosity requirements, Ar 70% + He 30% is used. Helium is characterised by 9 times the thermal conductivity of argon, faster welding speed, reduced porosity and increased depth of fusion. Depth of melt conditions for thick plate welding with Ar100% and Ar70% + He30%. The choice of gas flow rate is not the better, too large a flow rate can cause turbulence, resulting in inadequate protection of the molten pool, air reacting with the molten metal, which can change the weld tissue and degrade performance, and an increased tendency to produce welding porosity.

Aluminium welding preparation

The treatment of bevels The butt welds below 3mm thick may not be subject to beveling, but only the back of the weld can be chamfered -0.5mm to 1mm, which is conducive to the discharge of gas and to avoid back grooves. Whether the back is chamfered on the impact of the weld. The bevel angle for thick aluminium plates is larger than that for steel plates. A 55° bevel is generally used for single-sided bevels and a 35° bevel on each side is used for bilateral bevels. This improves the accessibility of the weld and reduces the chances of unfused defects.

For thick plate T-shaped joints in the HV or HY joints, the requirement to fill the bevel outside, and then add a corner weld, so that the total size of the weld S is not less than the plate thickness T. Thick plate T-shaped joints welding requirements.

Cleaning before welding

Welding aluminium alloys requires the cleanest preparation, otherwise their corrosion resistance is reduced and they are prone to porosity. Welding aluminium alloys should be thoroughly distinguished from the habit of welding steel. Tools that have already been used for welding steel should not be used for welding aluminium alloys. Clean the weld area from impurities such as oxide film, using a stainless steel brush or cleaning with acetone if possible. Abrasive wheels must not be used, as using them will only cause the oxide film to fuse to the surface of the weld without actually removing it. Furthermore, if a hard grinding wheel is used, the impurities in it can enter the weld and cause thermal cracking. In addition, as the Al2O3 film will regenerate and build up again in a very short time, the weld should be applied immediately after cleaning in order for the oxide film to affect the weld as little as possible.

Preheating temperature and interlayer temperature control

When welding thick plates with a thickness of more than 8 mm, they should be preheated before welding, with the preheating temperature controlled between 80 °C and 120 °C and the interlayer temperature controlled between 60 °C and 100 °C. The preheating temperature is too high, in addition to the harsh operating environment, there may be an impact on the alloy properties of the aluminium alloy, softening of the joint, poor weld appearance and other phenomena. A high interlayer temperature will also increase the chances of thermal cracking in aluminium welding.

Reasonable choice of specification parameters

Aluminium alloy and steel physical and chemical properties are very different, according to the welding characteristics of aluminium alloy to test and determine its welding specification parameters.

(1) Higher welding current

Aluminium alloy itself has a large thermal conductivity (about 4 times that of steel) and dissipates heat quickly. Therefore, at the same welding speed, the heat input when welding aluminium alloys is 2 to 4 times greater than the heat input when welding steel. If the heat input is not enough, it is easy to have insufficient depth of fusion or even not fused, especially in the position of the beginning of the weld.

(2) Wire feed speed should be adjusted appropriately high

Wire feed speed is closely related to the current, voltage and other parameters of the specification, and match each other. When the welding current is increased, the wire feed speed should also be increased accordingly.

(3) Selection of welding speed

For thin plate welds, in order to avoid overheating of the weld, generally use a smaller welding current and faster welding speed; for thick plate welds, in order to make the weld fusion fully and weld gas fully escape, use a larger welding current and slower welding speed.

(4) The choice of welding torch angle

In the welding direction, the angle of the welding torch is generally controlled at about 90°, too large and too small will cause welding defects. The angle of the torch will cause insufficient gas protection and pores; the angle is too small and may make the liquid aluminium to reach the front of the arc, so that the arc can not directly act on the weld and produce unfused.

Cleaning after welding

1、Carefully scrub the welded joint in hot water with a stiff brush.

2, the weld in the 60 ~ 80 ℃, mass fraction of 2% ~ 3% of chromic anhydride solution or potassium dichromate solution dip wash about 5 ~ 10min, and carefully scrubbed with a hard brush. Or put the welded parts in 15 ~ 20 ℃ mass fraction of 10% nitric acid solution in the dip wash for 10 ~ 20min.

3、Wash the solder in hot water.

4、Blow the welded parts dry with hot air or dry them in a drying oven at 100℃.

Protection measures

1、Remove the oxides from the workpiece bevel and surrounding parts and the surface of the welding wire by mechanical or chemical means before welding;

2、The welding process should be protected by qualified shielding gas;

3、When gas welding, use flux and continuously pick through the oxide film on the surface of the molten pool with the welding wire during the welding process.

Industry range

1, the refrigeration industry copper and aluminium tube sockets, central air conditioning copper and galvanised tubes, stainless steel tubes, aluminium tubes of different kinds of welding.

2、The welding of copper and aluminium terminals, copper and aluminium leads, and copper and aluminium conductive rows in the substation industry.

3、The welding of radiator tubes, motors and bus bars in the electrical and electronic industry.

4、Also used in the production life of taps, coupling connectors, matching nuts, etc.