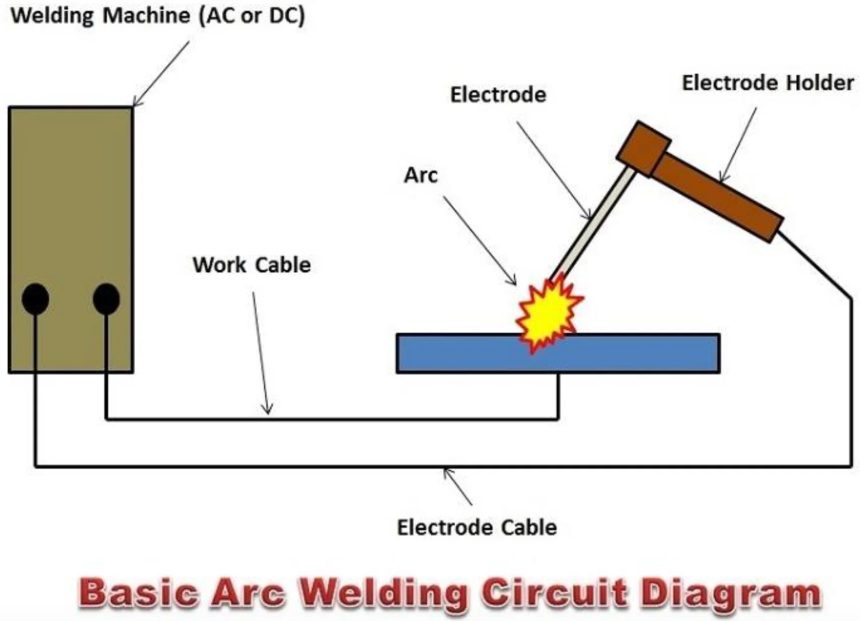

electricity to generate high levels of heat, which in turn melts the metals, creating a molten pool. As the metals cool and solidify, they fuse together, forming a single material. This fusion is the key factor behind the strength and durability of welded structures.

Arc welding is the process of melting two metals

Welding Town

Flux Cored Arc Welding (FCAW)

Flux Cored Arc Welding (FCAW) is a welding process that offers several notable characteristics:

- High productivity: FCAW is known for its high welding speed and efficiency, resulting in increased productivity compared to other welding methods.

- No external gas supply required: FCAW does not require an external shielding gas like MIG welding. The flux core of the electrode provides the necessary gas shield to protect the weld.

- Easy to transport: FCAW equipment is generally portable and easy to transport, making it suitable for on-site and remote welding operations.

- Not recommended for thin metals: FCAW is better suited for thicker materials and heavy-duty applications. It is less suitable for welding thin metals due to the higher heat input and potential for distortion.

- Can be used on dirty base metals: Flux-cored welding can be performed on dirty, rusty, or painted base metals, making it suitable for environments where the surfaces may not be perfectly clean.

- Some cleanup required: FCAW can produce slag and spatter, resulting in the need for post-weld cleanup. The slag can be easily removed when necessary.

The flux-cored arc welding process

The flux-cored arc welding process involves the following steps:

- Flux core electrode: The electrode used in FCAW contains a flux core composed of various compounds and powdered metals. This flux creates a gas shield when heated by the arc, protecting the molten electrode, filler metal, and base metal in the weld pool. The residual slag also provides additional protection.

- Drag technique: FCAW is typically performed using a drag technique, where the weld gun is angled back into the weld pool and pulled away from the completed weld.

Where is flux-cored welding used?

Flux-cored welding is commonly employed in heavy-duty industrial fabrication and manufacturing processes. It is not recommended for beginners or those with limited welding experience due to the complexity of the technique.

The absence of the need for a shielding gas makes flux-cored arc welding suitable for outdoor applications as well. It provides versatility and productivity in various welding projects, particularly those involving thicker materials and challenging conditions.