When using a TIG welder to weld aluminum, it can be a challenging process due to its higher heat requirements compared to mild steel. The voltage needed for aluminum welding typically falls within the range of 21 to 24 Volts.

Read ahead to find out more about pulse welding.

Welding Town

Bead Appearance

A weld bead refers to the accumulation of filler metal deposited during a single welding operation. With a pulsed MIG system, you have better control over the heat input, allowing you to create weld beads of the right size. This control is essential because different welding applications may require specific bead sizes for optimal results.

Larger bead sizes are beneficial for joining two sides of a joint effectively. They provide more filler metal, resulting in a stronger and more substantial connection between the two pieces being welded together.

On the other hand, smaller bead sizes are advantageous when you need precise and thorough fusion at the root of a joint. The controlled heat input from pulsed MIG ensures that the weld puddle is well-contained, leading to better fusion and penetration at the root.

Pulsed MIG welding also enhances the appearance of the weld bead, creating a more aesthetically pleasing result. In some cases, pulsed MIG can even be used as a substitute for AC TIG welding in certain welding applications.

In summary, a pulsed MIG system allows for better control over weld bead size, making it suitable for various welding tasks that require specific bead characteristics for optimal performance and appearance.

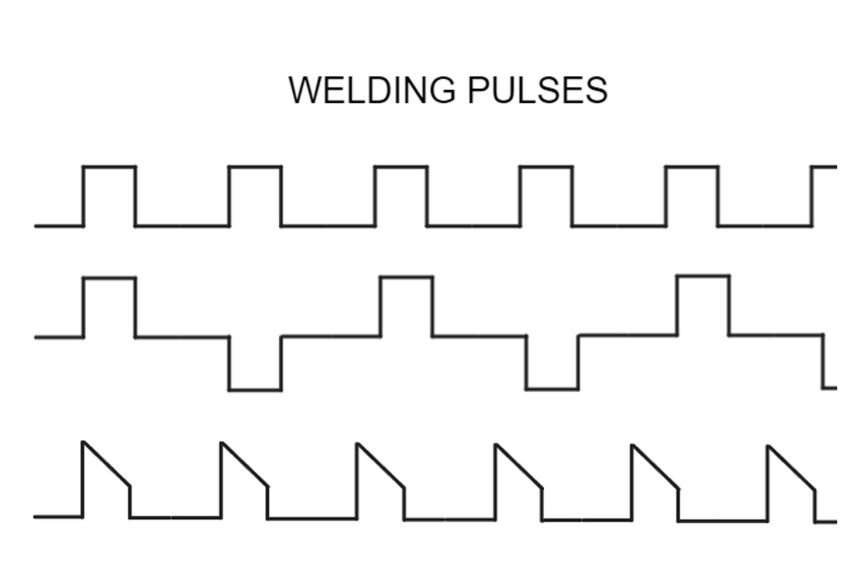

Pulse Duty

In pulse welding, there are two main levels of current known as the peak current level and the low current level. The pulse duty cycle refers to the balance of time between these two levels during the welding process.

For example, at a 50% pulse duty cycle, equal time is spent between the peak current level and the low current level. This means that the welding current alternates between the peak and low levels, spending an equal amount of time at each level. This balanced approach helps to control the amount of heat input into the weld and allows for more precise and controlled welding. Different pulse duty cycles can be used depending on the specific requirements of the welding application.

Advantages of Pulse Welding

Pulse welding offers several advantages that make it an ideal option for operators working with aluminum. One of the significant benefits is spatter-free welding.

When using traditional MIG welding, operators may encounter issues with spatter, which occurs when molten welded drops fall outside the welding puddle. Spatter can be a nuisance and may result from dirty wire or improper gun angles.

In contrast, pulsed MIG welding significantly reduces spatter and fumes during the welding process. This is because pulsed MIG applies much of the melting wire to the joint in a controlled manner, resulting in less splattering. As a result, cleanup time is reduced, making pulse welding a cleaner and more efficient option for welding aluminum.

Welding Thick and Thin Materials

Absolutely! One of the key advantages of a pulsed MIG system is its ability to shift between peak and low current levels. This flexibility allows operators to use a single wire to weld various materials of different thicknesses.

For example, let’s consider a 1.2mm wire. At a lower setting of around 26 amperes, this wire can weld thin sheets of approximately 0.6mm thickness. However, the same wire can also handle much thicker materials when set at a higher current level, such as 500 amperes.

This versatility in current control enables pulsed MIG welding to work with a wide range of metals and thicknesses, making it a highly efficient and adaptable welding method. Operators can seamlessly transition between different welding tasks without changing wires, increasing productivity and convenience.