When using a TIG welder to weld aluminum, it can be a challenging process due to its higher heat requirements compared to mild steel. The voltage needed for aluminum welding typically falls within the range of 21 to 24 Volts.

Read ahead to find out more about pulse welding.

Welding Town

Eliminating Wire Change

Indeed, the advantage of a pulsed MIG system’s versatility extends to its cost-effectiveness and inventory management. Unlike a regular MIG system, where different wire diameters are required for various thicknesses, a pulsed MIG system can effectively handle different thicknesses using a single wire diameter.

This reduction in the need for multiple wire diameters significantly lowers the inventory costs for welding materials. Additionally, fewer spare parts are required for maintenance, further reducing expenses. Moreover, operators save valuable time that would have been spent changing wires for different welding tasks.

For aluminum welding, where thicknesses can vary widely, a pulsed MIG welding system proves to be a preferred choice due to its ability to handle diverse thicknesses with a single wire. The cost savings and convenience provided by a pulsed MIG system make it an attractive option for welding operations that work with aluminum and other materials of varying thicknesses.

Better Penetration

You’re absolutely right. Weld penetration is a crucial aspect of welding, and achieving the right level of penetration is essential for creating strong and durable welds. In a pulsed MIG system, the balance of heat and penetration is achieved by alternating between peak and low currents during the welding process.

Pulsed MIG welding is known for its ability to provide deep and maximum penetration, making it ideal for creating robust welds. By carefully controlling the current levels, pulsed MIG systems can achieve deeper penetration for each ampere used, resulting in stronger welds compared to shallow penetration achieved by conventional MIG systems.

In summary, the ability of pulsed MIG welding to offer deeper penetration contributes significantly to the overall strength and quality of the welds, making it a preferred choice for various welding applications.

Disadvantages of Pulse Welding

While pulse welding offers numerous advantages, there are also some disadvantages to consider when compared to standard MIG welding:

Cost: Pulsed MIG welding equipment can be more expensive than standard MIG welding machines. The added technology and features of pulse welding systems contribute to the higher cost.

Complexity: Pulsed MIG welding systems can be more complex and require additional training for operators to effectively utilize the pulse settings and control the welding process.

Maintenance: Due to the more sophisticated technology involved, pulse MIG welders may require more frequent maintenance and calibration to ensure consistent performance.

Limited Positioning: Pulsed MIG welding is highly effective for horizontal and flat positions, but it may not be as suitable for out-of-position welding, such as vertical or overhead welding.

Heat Management: While pulse welding can control heat input better than standard MIG, improper settings or operator error can still result in issues like burn-through on thinner materials or inadequate fusion on thicker materials.

Wire Selection: Pulsed MIG welding may require specific types of wires to achieve optimal performance, which could limit the range of materials that can be welded.

Despite these disadvantages, pulse MIG welding remains an excellent choice for certain applications, especially when working with aluminum and other challenging materials that require precise control over the welding process. It’s essential to assess the specific requirements of your welding projects and consider the advantages and disadvantages of both pulse and standard MIG welding before making a decision.

Recommended Settings on TIG/MIG for Steel and Aluminum

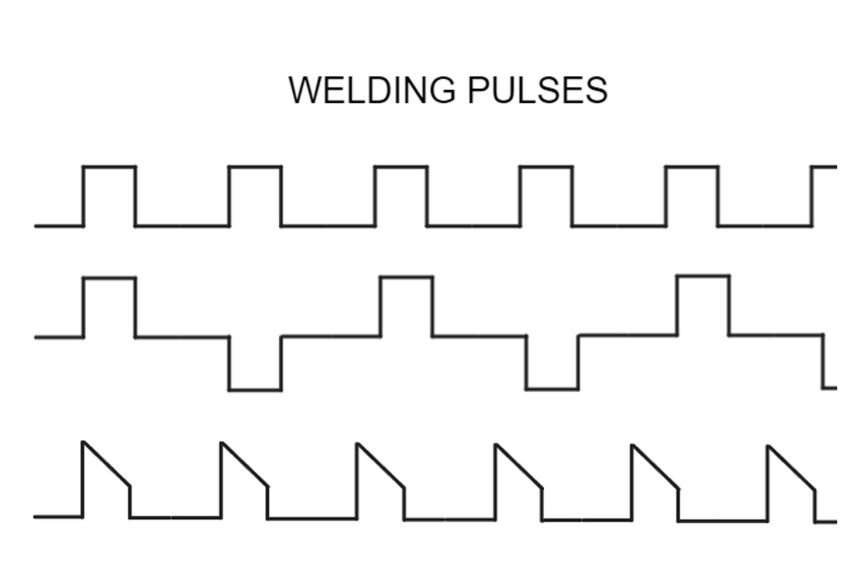

Pulse frequency, in welding, refers to the number of times the welding current switches between low and high levels in one second. It is measured in Hertz (Hz). For example, if you set the pulse frequency to 0.5 Hz, it means there will be one pulse every two seconds. If you set it to 100 Hz, there will be 100 pulses per second.

The pulse frequency setting plays a crucial role in achieving different welding outcomes, especially when using a pulsed MIG system or TIG welding on different materials:

Welding Aluminum: A lower pulse frequency, such as one pulse per second or less, can make the filler rod easier to feed and keep it in sync with the pulse. This setting is suitable for achieving a uniform weld. For thicker aluminum materials, a higher pulse frequency may be appropriate, such as around 100 Hz.

Welding Steel: For TIG welding on steel, starting with a power of about 200 amperes and a frequency of around 100 Hz is recommended for 5mm aluminum. As you gain experience, adjusting the amperage based on the material thickness (1 ampere for every 0.001-inch thickness) and using the foot pedal for varying amperage can help achieve the desired results.

Welding Mild Steel with MIG: For pulsed MIG welding on mild steel, the settings may vary depending on the wire diameter and material thickness. Common wire sizes are 0.8mm, 0.9mm, and 1.2mm, which should be used with low currents to minimize splatter.

Finding the right pulse frequency and other settings for specific welding applications often requires practice and adjustments based on the type and thickness of the material being welded. It’s essential to test and refine the settings to achieve optimal results in the welding process.