As you probably know by now, shielding gas is used to shield or protect a MIG or TIG weld pool from oxygen and nitrogen and other contaminants that negatively affect the weld.

Shielding Gas

Welding Town

MIG Gas Tips

Usually, gas mixtures for MIG welding is a blend of carbon dioxide and argon.

The main job of the shielding gas is to cover the mouth of the weld and keep it from coming in contact with oxygen and nitrogen and the surrounding air, but these gases also affect the characteristics of the arc itself.

The most common mixture of shielding gas is 75% argon and 25% C02. The way you see these percentages on a chart or in articles is like this: 75/25.

- Make sure bottle is chained up so doesn’t fall.

- 100% C02 is a great way to go if you want to save money, but you are going to have a lot of spatter. On the positive side you will get deeper penetration of your weld.

- If you want a good weld without spatter then you’re going to have to mix it up, and it’s going to cost more for the mixture. 75/25 common = 75% argon, and 25% co2. You’ll get the best aesthetics from this mix.

- Try using an 85/15 mixture for heavier material (plate) and may have mill scale.

- To get spray transfer a 90/10 gas mixture is good for use on heavy or thick metal.

Aluminum MIG Welding Gas Mixture Tips

Argon is used for mig welding because it has good cleaning abilities and helps you penetrate the material. If you are welding 5XXX aluminum you will want to mix it with helium. Using up to 75% helium will keep magnesium oxide build up to a minimum.

Whether you are GMAW (MIG) welding or GTAW (TIG) Welding, shielding gas mixes are not perfect and there are many arguments about what is best for the type of material.

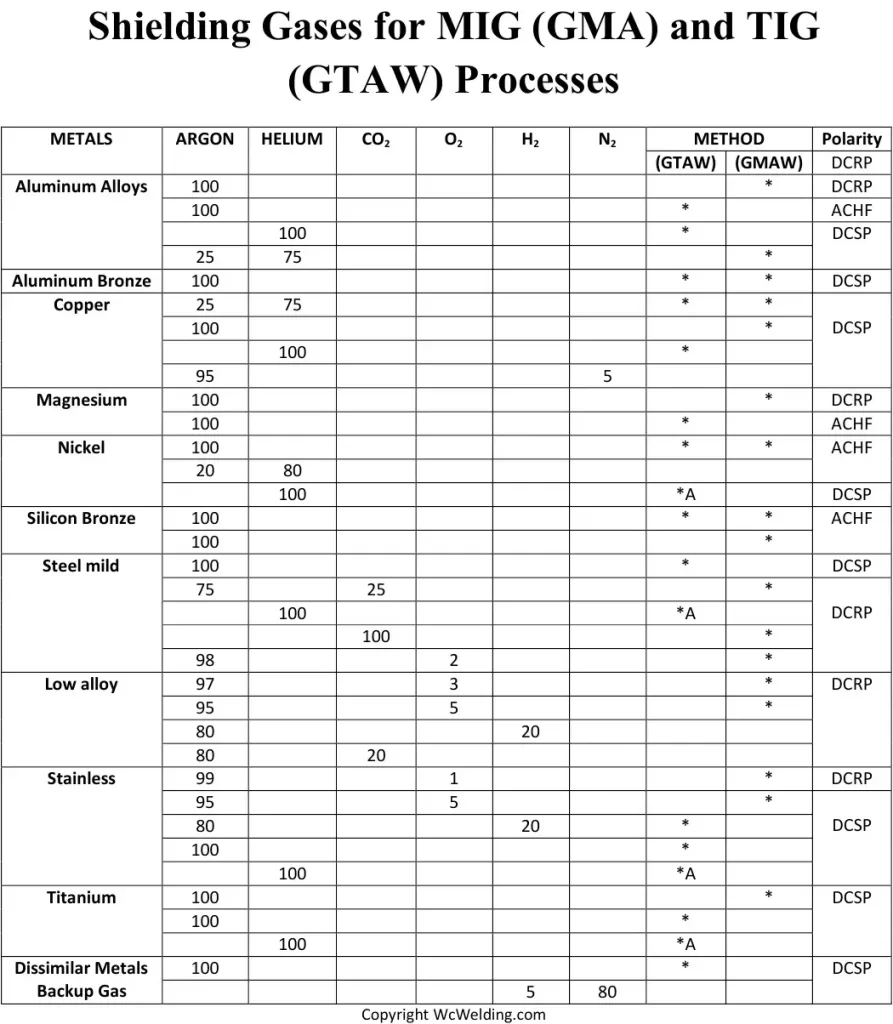

Below is a chart for recommended shielding gas mixes for MIG and TIG welding.

MIG Welding Gas Guide

The shielding gas for MIG or TIG has a significant effect on the parent metal. The metal thickness, metal type, and gas mixture affect each of the following differently:

- Weld aesthetics.

- Travel speed.

- The quality of your weld.

- Weld bead aesthetics.

- How smooth the welding process is.

GMAW (MIG) Gases

Argon: It’s heavier than air and therefore it covers the the weld and protects it from the air which will contaminate the weld otherwise. It is very good cleaning action compared to the other gases.

Argon creates a stabler arc but is frequently used with other gases to achieve better results.

Argon produces less spatter because the arc does not require as many volts therefore you use less power, but this also means you get less penetration of your weld. Less spatter and penetration of the material is good for welding sheet metal.

100% argon is rarely used unless you are going to weld metals like titanium, copper, nickel, or aluminum.

If you try using 100% argon on steel you will probably get a lousy bead, low penetration of the weld, and undercutting on the edges of the weld. None of these things are good.

Argon and Oxygen: A little bit of oxygen can produce more than satisfactory results. Even in amounts of just 5% or less. You’ll get better weld penetration, and a nicer weld bead, and you will not get any undercutting.

An argon and oxygen mixture is for welding stainless steel, carbon steel, or alloy steel.

Helium: This is another type of inert gas used in shielding and it can mixed with other gases.

Helium is the exact opposite of argon in that it is lighter than air.

MIG welding with helium: the energy in the arc is not very significant compared to argon, and therefore the weld bead is going to be wider, with poor penetration.

TIG welding with helium: The opposite is true in comparison to MIG welding with helium. TIG welding with helium results in faster travel speed and better weld penetration.

It costs more so it should only be used on specific projects or for welding metals such as copper, magnesium, or aluminum.

Carbon Dioxide: CO2. This gas is for MIG welding mild steel. It is cheaper compared to other gases, but it’s usually mixed with other gases as well, depending on the type of metal you will be welding.

Some of the negatives are that it can create a chaotic arc which results in a spatter. But the positives of using C02 are significant; deeper penetration.

You will want to mix this gas with argon for MIG welding steel. 75/25 is the most common mixture that provides good penetration, a nice weld, and almost no spatter.

Tig Welding Shielding Gas Tips

The main shielding gas used in GTAW (TIG) Welding is Argon. For many applications, you’ll be using 100% argon. But there are different mixes to consider with helium for different metals and thicknesses as well (see chart above).

Warning: Do not use an argon/C02 mixture. You’ll get contamination of your weld.

The reason argon is used in TIG welding is that it conducts heat at a mild rate and helps in producing a thin arc which is easier to control; you will be able to vary the arc length without disrupting the heat of the arc and therefore the quality of your weld bead.

Also, you’ll get quality starts because it carries the current well.

Helium is also used in TIG welding. But usually only when welding thicker aluminum, .25 inches more.

If you are going to be TIG welding in AC, you’ll want argon rather than helium because it’s more of a ‘cleaner’, and has better stability of the arc and overall aesthetics of the weld.

There are even times when you may need to use nitrogen or hydrogen. But for most of us garage-type welders, we’ll be dealing mostly with argon and helium mixes.

But an argon and helium or argon hydrogen mixture may be needed if you require a faster travel speed.

GTAW (TIG) Gases:

TIG welding shielding gases will be argon helium or a mixture of the two. But argon is the most commonly used shielding gas for TIG welding.

If you want a more stable arc and good cleaning action then argon is the gas you want for TIG welding.

As described above, argon is heavier than air and therefore can provide good coverage of your weld pool which will keep contaminants of your weld out.

On the other hand, you have Helium. It is lighter than air. So, you’ll have to increase the gas flow to get decent coverage of your weld. As a result, you’ll be shelling out more money for helium.

But, helium has it’s usefulness. It will give you better weld penetration, and you can weld at a higher speed with it. The reason you have a faster travel speed is because helium will give you an arc that is hotter in comparison to using argon as the shielding gas.

See the shielding gas chart above which shows you the gas mixtures for the different welding processes and the types of metal you want to weld. On this chart you will observe that 100% argon is the most common gas for most metals.