The gas used as the shield purpose is Argon gas in TIG welding. The full form of TIG is Tungsten Inert Gas, and is known as the heat source or electrified tungsten. The weld is protected from the environment by inert gas or argon gas, it means the gas is not corrosive or inflammable and it prevents oxidation.

Argon Tig Welding

Welding Town

The material tungsten is used to make the filaments in incandescent light bulbs. It is used for both heat and light when electricity passes through it. In argon TIG welding, welders use the electrode which is more massive than light bulb filament, in order to create a steady heat source of up to about 11000 degrees.

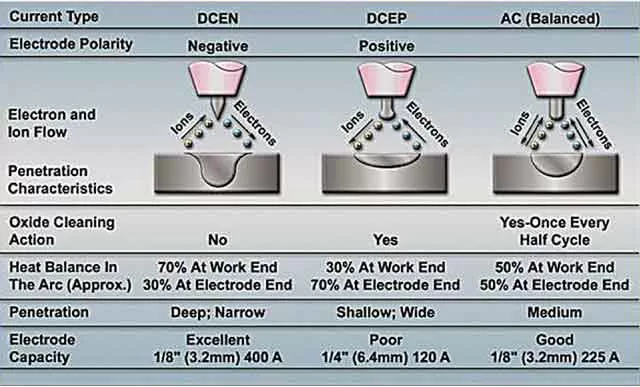

The electrode’s diameter and length, and the kind and amperage of current find its heating properties and different electrodes are accurate for different applications.

Now let’s check

Why Is Argon Used in Welding, and What Is It?

What exactly is Argon?

It is a chemical element (Ar), and the most abundant gas in the environment, which makes it available on a large scale & comparatively cheap. The production of argon is done by distillation of liquid air. Then it is put in gas vessels and sold commercially in the market. The different welding techniques are run by Argon gas widely. The Argon welding gas acts as a shield for the fresh weld of its surrounding environment.

And it really advantages making the welds more seamless and durable. Now let’s talk more about the gas in the article below:

Why is Argon gas used in welding?

The “laziness” of argon gas is really that makes it useful to us and that’s why it is utilized in welding. It happens because there is a lack of any reaction between argon and other elements. Being an inert gas it acts a great purpose in shielding the environment while in the TIG welding argon is being dispersed straight by the tip of the welder, surrounding the arc and their food, restricting the impact of moisture and other elements that otherwise may make the weld brittle.

Its shielding nature and also known as noble gas is used in TIG & MIG welding. Some other gases like nitrogen, Oxygen, and carbon dioxide are also utilized in different kinds of welding procedures. By grouping these gases can provide even better results for some situations.

For example, if you wish different gases combinations for welding steel and when welding aluminium. Most industries are experimenting with the thickness of different combinations of gases and thickness of metals to set up etalons.

Although the method of the welder will also play a great role, it’s not always possible to come up with a solution for all purposes in welding.

Argon and CO2 is a well known combination, specifically for welding thin sheets of steel. Pure argon solution is also available commercially, so the group between argon and oxygen works best.

Is argon non inflammable?

Yes it is and does not support combustion. With the tig welding techniques sometimes reaching 7000 degree Fahrenheit or 3871 degree centigrade, it’s a secure choice for welders.

The non poisonous nature of Argon?

Being inflammable it’s also non toxic. But there can be health related issues when using argon gas. The gas is also characterized as a simple asphyxiant, and by using it decreases oxygen content in the air. It might be wonderful for arc welding, but it’s not good for oxygen dependent welders.

Note: a well ventilated space is recommended when argon is used for welding.

The reaction of argon with other gases in tig welding

It’s a noble gas and nonreactive with other gases.

It comes under inert gases because they do not easily react with other compounds or elements. It is possible for organ gas to react with other elements if you are splitting chemical hairs. Although it would take extreme techniques to induce a reaction.

Other benefits of using Argon gas by welders

- It is a low cost gas

- Having shielding gas capabilities

- More stability

- Non reactive nature and noncombustible so its exposed to the extreme temperature during welding

- It’s present naturally in the earth atmospheres and affordable for welders

Conclusion

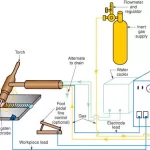

As we learned about the argon TIG welding gas, it is perfect for shield welding as it disperse contaminating elements in the environment and protects welds from corrosion and oxidation. Welders also used regulators and flow meters to regulate the flow of the argon from the gas tank to the welding torch.