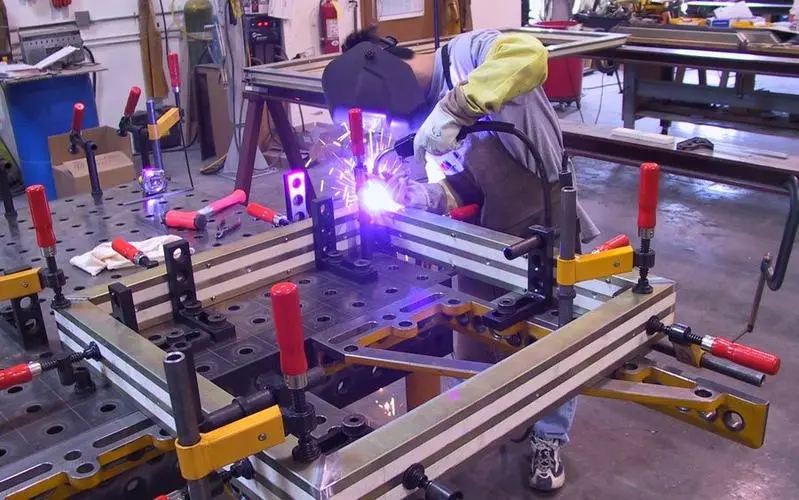

For beginners, diving into welding might feel intimidating due to the potential hazards and the array of welding tools involved, as working with heat and pressurized components can be overwhelming.

10 ESSENTIAL WELDING TOOLS FOR EVERY WELDER

Welding Town

However, there is no need to fear; I present to you a list of the top welding tools that newcomers can use to learn the trade safely and effectively:

Auto-Dimming Helmet

The welding helmet holds a prominent place in the welding trade and is an essential safety tool. Among all welding equipment, it is the most fundamental and recognizable. The primary purpose of any welding helmet is to protect your face from burn scars caused by sparks and flames during work. Additionally, it serves to shield your skin and eyes from heat-related damage.

Auto-darkening helmets offer an additional advantage by protecting your eyes from the intense lights emitted by other welding tools and the heated metal. These helmets use shaded glass above your eyes that allows only a specific amount of light to pass through at any given time. This feature ensures that you can see clearly without risking harm to your eyes.

WELDING GLOVES

Welding gloves are self-explanatory in their purpose. They are designed with multiple layers of durable materials and insulation to shield users from the heat and flying sparks associated with welding. These gloves are readily available in stores selling welding equipment and are an indispensable necessity for any welding work you undertake.

There are two main types of welding gloves to be mindful of:

MIG Welding Gloves: These gloves are typically thicker and come with padding on the back of the hand. They serve to protect the resting hand while bracing the dominant hand during a weld. The loose-fitting design allows for easy removal of the glove if it becomes too hot.

TIG Welding Gloves: These gloves are softer and thinner, specially tailored for tasks where precision is crucial, such as TIG welding. Due to the precision required, these gloves fit snugly, enabling accurate movement while holding the rod and flame.

It is vital to ensure you wear the appropriate type of gloves for the specific welding task at hand. By doing so, you can work safely and effectively, maintaining control and dexterity while protecting your hands from potential hazards.

WELDING PLIERS

MIG pliers are readily available for purchase online and at most hardware stores. Despite their versatility and usefulness, they are not specialized tools and are reasonably priced.

These pliers can be employed for various tasks, such as:

Removing the Nozzle from the MIG Gun: Equipped with circular clamps, MIG pliers are perfect for easily taking nozzles out of MIG guns. It is necessary to loosen and tighten the contact tip frequently as it wears out over time.

Saving Time on Stick-Out Cutting: MIG pliers offer the advantage of saving time by cutting 1/4″ of the stick-out without the need for a separate wire cutter.

Removing Weld Spatter: With their handy tips, the pliers can effectively clean the inside of the nozzle from weld spatter, making the task easy and efficient.

These versatile MIG pliers are a valuable addition to any welder’s toolkit, providing convenience and enhanced performance while handling various welding-related tasks.

C CLAMP

C clamps are a type of clamps that have a distinctive C-shaped appearance. Their utility extends beyond welding, as they are widely used for various hardware tasks. One of their key advantages is their ability to apply pressure from both above and below the clamped object simultaneously. This unique feature allows for a more secure and stable grip compared to pinch clamps or certain welding clamps.

Thanks to their design, C clamps can exert greater pressure, making them ideal for firmly holding and securing objects during a wide range of applications. Their versatility and robust gripping capability make them an indispensable tool in many workshops and industries.

WELDING BOOTS

Foot injuries are among the most common yet often overlooked workplace mishaps. Shockingly, they account for approximately 25% of all disability applications resulting from work-related incidents, as estimated. When engaging in welding activities, it is crucial to take precautions to safeguard your feet from potential hazards posed by hot metals and heavy tools.

For this reason, investing in a reliable pair of welding boots is imperative. These boots must prioritize durability, ensuring they can withstand the rigorous demands of welding tasks. Strong leather and steel-toe shoes are essential features to consider when choosing the appropriate welding boots. The primary goal is to provide adequate protection to your feet, shielding them from potential harm caused by falling molten metal or any other welding-related hazards.

By wearing high-quality welding boots, you significantly reduce the risk of foot injuries, allowing you to work safely and confidently while focusing on your welding projects. Remember, protecting your feet is just as important as any other safety measure in the welding environment.

METAL FILE

The primary purpose of a metal file is to eliminate burrs and jagged edges from the metal that you have cut, similar to the function of an angle grinder. Metal files are tools that you have likely used at some point in the past, and they find frequent application in various metalworking projects. Files are instrumental in providing a smooth finish and imparting a pleasing appearance to the final product.

On the other hand, angular grinders serve a different role – their main objective is to remove undesirable materials from the metal. While metal files refine the surface and create a polished finish, angular grinders are employed to take away unwanted material, leaving a clean and even surface behind.

Both metal files and angular grinders are valuable tools in the metalworking realm, each contributing unique capabilities to enhance the overall quality and appearance of the finished metalwork.

ANGLE GRINDER

An angle grinder is an incredibly useful cutting tool that proves essential in any welder’s toolbox, particularly for those who weld regularly. Its versatility is evident in its ability to cut various types of metal. At some point in your welding projects, you will need to trim metal stock, and an angle grinder comes in handy for this task. With a cutting wheel, you can easily cut through materials such as sheet metal and bar stock with surprising ease.

Moreover, angle grinders play a vital role in preparing metal for welding. Before beginning the welding process, it is crucial to clean the base metal thoroughly to avoid potential flaws like porosity and cracking in the weld. While a wire brush can be used for this purpose, employing an angle grinder significantly reduces the time and effort required for proper metal preparation.

In summary, having an angle grinder in your arsenal offers immense benefits to welders. Its cutting capabilities and efficient metal preparation make it an indispensable tool for producing high-quality welds and enhancing overall welding performance.

SAFETY GLASSES

Wearing a welding helmet is not always necessary; there are instances when it may be considered excessive protection. In such situations, a reliable pair of safety glasses suffices. Safety glasses are made of durable plastic and effectively shield your eyes from potential hazards, including sparks that may fly while using tools like an angle grinder.

While welding helmets provide comprehensive protection, safety glasses are a practical alternative for certain tasks that do not involve intense welding work. They offer adequate eye protection and help prevent any debris or sparks from causing harm to your eyes. When you find yourself in situations where a welding helmet may be unnecessary, safety glasses are the ideal choice to maintain safety without compromising comfort and visibility.

WELDING MAGNETS

A welding magnet is undeniably one of the most valuable items to have in your toolbox, especially during welding tasks. Its usefulness becomes apparent as it simplifies and enhances welding processes significantly. With the aid of a welding magnet, metal components can effortlessly remain in place without the need for clamps, streamlining the welding procedure.

Moreover, welding magnets enable the attachment of metal parts and facilitate welding them together at various angles. This functionality proves especially beneficial in sheet metal welding, where traditional clamps may not offer the same level of versatility. As you become more acquainted with welding, you will discover an array of applications for welding magnets, further amplifying their utility in your welding projects.

In essence, welding magnets provide remarkable convenience, stability, and adaptability, making them an indispensable tool for welders seeking efficient and effective metal joining solutions. Their versatility and ease of use make them a valuable asset that simplifies various welding tasks and improves the overall welding experience.

SPEED SQUARE

A speed square is undeniably one of the most frequently used tools from the list provided. Its versatility and functionality make it an essential instrument in welding projects. With a speed square, you can easily measure and create precise 90-degree cuts or any other angles as needed.

This angular measuring tool features a right triangular shape, enabling you to make multiple measurements at various angles with ease. Whether you require perfect right angles or custom angles for your welding work, the speed square provides accurate measurements for precise cuts and joins.

Among all the welding tools at your disposal, the speed square is likely to be the one you reach for most frequently. Its reliability in providing accurate measurements is indispensable in achieving successful welding outcomes. Remember, precise measurements are the foundation of quality work in welding, and the speed square plays a crucial role in ensuring your projects are well-crafted and efficient.

CONCLUSION

In conclusion, for beginning welders, MIG welding is a recommended starting point to get familiar with the trade, as mentioned earlier. As you embark on your welding journey, you will discover the immense value of all the items listed here. Each tool serves a specific purpose and proves indispensable in various welding tasks. These tools will be invaluable companions as you continue to refine your welding skills and expertise over the years.

Remember, practice and experience are key to becoming a proficient welder, and the tools in your toolbox will play a significant role in supporting your growth. Embrace the learning process, utilize these essential welding tools, and you will find yourself achieving remarkable results in your welding endeavors for years to come. Happy welding!

To get the hang of the trade, beginning welders should start with MIG welding, as was already said. You will find tremendous use for all items on this list as you learn to weld. Many of them you will continue to use for many years to come.