In the metal fabrication sector, welding and soldering are vital techniques employed to join metal pieces by applying heat. To draw a comparison between welding and soldering, various factors will be considered, such as metal temperature, heat source, flux usage, and deformation. However, before delving into their differences, it is essential to grasp the fundamental principles of welding and soldering.

Difference Between Soldering And Welding

Welding Town

What Is Welding?

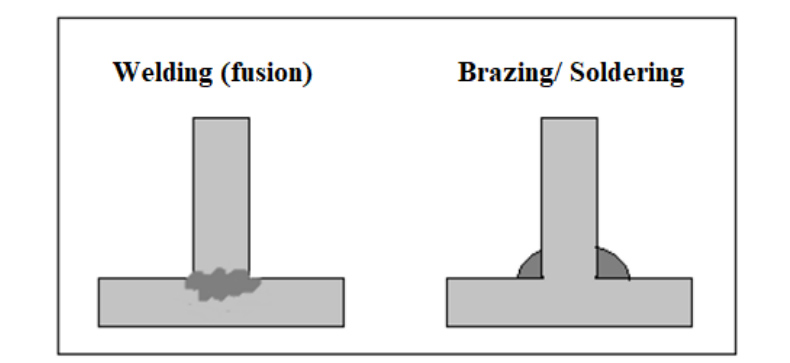

Welding serves as a fabrication technique that entails applying intense heat to melt the parts, enabling them to cool and fuse together to unite various materials, including metals or thermoplastics.

During welding, the two objects are joined by combining heat and a filler substance. The filler material may pool between the bonded items when heated to its melting temperature. The end result is a solid joint, commonly known as a weld. Several welding procedures, such as gas welding, arc welding, resistance welding, forge welding, and others, are categorized based on the specific techniques used to join the objects.

What Is Soldering?

Soldering is a fabrication technique utilized to fuse two objects by melting and introducing a filler substance into the joint. Unlike welding, the filler material used in soldering has a lower melting point compared to the base metal or adjacent metals. During the soldering process, the base metal or workpiece itself is not melted.

The solder, which acts as the filler metal, is melted using heat from a soldering iron. It reaches a temperature of approximately 316 °C, surpassing its melting point, causing it to liquefy and form the soldering joint upon cooling. Soldering finds primary application in creating strong joints on electrical and electronic circuit boards. Flux, a substance used in soldering, reinforces and enhances the joint’s mechanical and electrical qualities.

Soldering can be categorized into three main types based on the temperature range:

Soft soldering (between 90 and 450 °C).

Hard (or silver) soldering at temperatures greater than 450 °C.

Brazing (over 450 °C).

Difference Between Soldering And Welding

| Factors That Differ | Welding | Soldering |

|---|---|---|

| Meaning | The method of combining materials—often metals or thermoplastics—is by melting the components under pressure, allowing them to cool, and then fusing them. | Soldering is a connecting technique that involves melting a filler substance (solder) to combine several types of metals. |

| Fusion Of Base Metal | The base metals are fused to form a joint during welding. | A filler substance creates the junction rather than the base metals fusing in soldering. |

| Temperature | The ideal temperature for welding is much higher than 3800 °C. Typically, the base metal’s melting point is above the welding temperature. | Below the melting point of the base metal, soldering is done at a very low temperature. Less than 400 °C is the normal soldering temperature. |

| The Joint’s Strength | The welds are sturdy enough to support the weight. In most cases, the welding connection is stronger than the base metal. | Because soldering joints are less strong than welding joints, they cannot support the load. |

| Filler Material | The use of filler material is not required throughout the welding process. The type of welding determines whether fillers are required. | A filler substance (also known as solder) is necessary for soldering. |

| High-Temperature Effects | The joint, after welding, can tolerate high temperatures. | The soldered joint begins to degrade as the temperature rises since it cannot resist high temperatures. |

| Flux Is Needed | The use of flux is optional when welding. | It is necessary to use flux when soldering. |

| Heat Source | Heat is typically generated during welding via electric arcs, resistance, gas flames, plasma, laser beams, etc. | Soldering irons, electrical resistance, ovens, ultrasounds, and other heat sources are frequently used for soldering. |

| Workpiece Deformation | The workpiece deforms significantly when welding. | The possibility of base metal deformation during soldering is extremely low. |

| Distortion | The welding process causes a significant amount of distortion to the piece. | The soldering process does not cause any distortion to the base metal. |

| Alteration To The Base Metal’s Microstructure | The base metals’ microstructure, or characteristics, has changed. | The basic metal’s microstructure remains unchanged. |

| Fusing Of Different Metals | The joining of different metals is challenging in welding. | Soldering makes it simple to join metals that are not compatible. |

| Fusing Together Thin Sheets | The joining of thin metal sheets is particularly challenging due to the high temperatures used in the welding process. | Thin sheets can be quickly bonded with soldering. |

| Tensile Power | A welding joint has a tensile strength of more than 200 mega Pascals. | A soldering joint has a tensile strength of under 75 mega Pascals. |

| Workpiece Heating And Melting | In the welding process, the base metals or workpieces are heated and melted. | Melting and heating of workpieces or base metals are not necessary for soldering. |

| Heat Treatment Is Required | Heat treatments are always necessary for welding. | In soldering, heat treatments are never necessary. |

| Preheating | The workpieces don’t need to be heated before welding. | Preheating the workpiece before soldering is not required, however, it may result in a high-quality bond. |

| Need A Qualified Operator | It requires specialized skills to weld. | Soldering does not require any specialized expertise. |

| Power Use | Welding uses more energy. | Low power consumption is used in soldering. |

| Application | Most mechanical industries, including those that make cars, airplanes, and ships, require welding. | For designing circuit boards and other purposes, soldering is mostly employed in the electrical and electronic sectors. |

In conclusion, this post has highlighted several significant differences between welding and soldering, showcasing their respective applications and benefits. Both welding and soldering are valuable techniques used for joining metallic components. The primary distinguishing factor lies in the melting of the base metal, which occurs during welding but not in soldering. Each method serves distinct purposes and plays a crucial role in various industries and applications. Understanding these differences helps in choosing the appropriate technique based on the specific requirements of the project or task at hand.